Kawasaki Z400 - Service manual > Wheels/Tires

Kawasaki Z400 - Service manual > Wheels/Tires

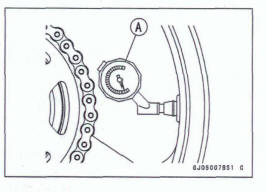

Air Pressure Inspection

- Remove the air valve cap.

- Measure the tire air pressure with an air pressure gauge [A] when the tires are cold (that is, when the motorcycle has not been ridden more than a mile during the past 3 hours)

Adjust the tire air pressure according to the specifications if necessary.

Air Pressure (when Cold)

Front: 200 kPa (2.00 kgf*m/cm², 28 psi)

Rear: 225 kPa (2.25 kgf/cm², 32 psi)

- Install the air valve cap.

Wheels and Tires Inspection

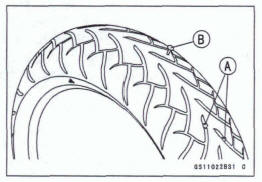

Wheel/Tire Damage Inspection

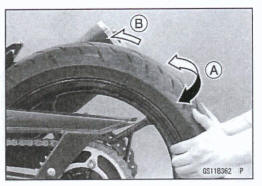

- Remove any imbedded stones [A] or other foreign particles [B] from tread.

- Visually inspect the tire for cracks and cuts, and replace the tire if necessary. Swelling or high spots indicate internal damage, requiring tire replacement

- Visually inspect the wheel for cracks, cuts and dents damage.

If any damage is found, replace the wheel if necessary.

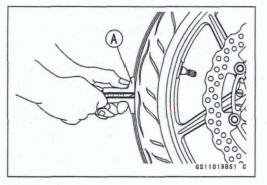

Tire Tread Wear Inspection

As the tire tread wears down, the tire becomes more susceptible to puncture and failure. An accepted estimate is that 90% of all tire failures occur during the last 10% of tread life (90% worn). So it is false economy and unsafe to use the tires until they are bald.

- Measure the tread depth at the center of the tread with a depth gauge [A]. Since the tire may wear unevenly, take measurement at s8ml places.

If any measurement is less than the service limit, replace the tire (see Tire Removal/ Installation in the Wheels/Tires chapter).

Tread Depth

Standard:

Front 4.0 mm (0.16 In.)

Rear 6.0 mm (0.24 In.)

Service Limit:

Front 1 mm (0.04 in.)

(AT, CH, DE) 1.6 mm (0.06 in.)

Rear 2 mm (0.08 In.)

(Up to 130 km/h (80 mph))

3 mm (0.12 In.) (Over 130 km/h (80 mph))

WARNING

Some replacement tires may adversely affect handling and cause an accident resulting in serious injury or death. To ensure proper handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure.

NOTE

- Most countries may have their own regulations a minimum fire tread depth: be sure to follow them.

- Check and balance the wheel when a fire is replaced with a new one.

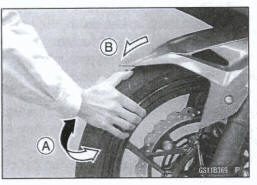

Wheel Bearing Damage Inspection

- Raise the front wheel off the ground with a suitable stand.

- Turn the handlebar all the way to the right or left.

- Inspect the roughness of the front wheel bearing by pushing and pulling [A] the wheel.

- Spin [B] the front wheel lightly, and check for smoothly turn, roughness, binding or noise.

If roughness, binding or noise is found, remove the front wheel and inspect the wheel bearing (see Front Wheel Removal, Hub Bearing Inspection in the Wheels/Tires chapter).

- Raise the rear wheel off the ground with a suitable stand.

- Inspect the roughness of the rear wheel bearing by pushing and pulling [A] the wheel.

- Spin [B] the rear wheel lightly, and check for smoothly turn, roughness, binding or noise

If roughness, binding or noise is found, remove the rear wheel and inspect the wheel bearing (see Rear Wheel Removal, Hub Bearing Inspection in the Wheels/Tires chapter).

See also:

Kawasaki Z400 - Service manual > Engine Top End

Kawasaki Z400 - Service manual > Engine Top End

Valve Clearance Inspection NOTE

Kawasaki Z400 - Service manual > Final Drive

Kawasaki Z400 - Service manual > Final Drive

Drive Chain Lubrication Condition Inspection Lubrication is necessary after riding through rain or on wet roads, or any time that the chain appears dry. Use a lubricant for sealed chains to prevent deterioration of chain seals. If the chain is especially dirty, clean it using a cleaner for sealed chains following the instructions supplied by the chain cleaner manufacturer.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03