Kawasaki Z400 - Service manual > Final Drive

Kawasaki Z400 - Service manual > Final Drive

Drive Chain Lubrication Condition Inspection

Lubrication is necessary after riding through rain or on wet roads, or any time that the chain appears dry.

Use a lubricant for sealed chains to prevent deterioration of chain seals. If the chain is especially dirty, clean it using a cleaner for sealed chains following the instructions supplied by the chain cleaner manufacturer.

NOTICE

The O-rings between the side plates seal in the lubricant between the pin and the bushing. To avoid damaging the O-rings and resultant loss of lubricant, observe the following rules.

Use only kerosene or diesel oil for cleaning of the O-ring of the drive chain. Any other cleaning solution such as gasoline will cause deterioration and swelling of the O-ring. Immediately blow the chain dry with compressed air after cleaning. Complete cleaning and drying the chain within 10 minutes

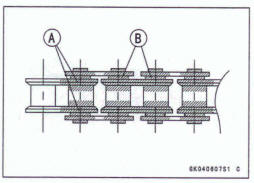

- Apply oil to the sides of the rollers so that oil will penetrate to the rollers and bushings. Apply the oil to the O-rings so that the O-rings will be coated with oil.

- Wipe off any excess oil.

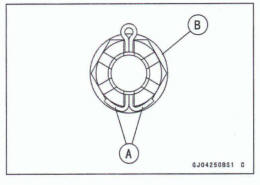

Oil Applied Areas [A] O-rings [B]

- Wipe off lubricant that gets on the tire surface

Drive Chain Sack Inspection

NOTE

- Check the siack with the motorcycle setting on its sidestand.

- Clean the chain if it Is dirty, and lubricate it if it appears dry.

- Check the wheel alignment (see Wheel Alignment Inspection).

- Rotate the rear wheel to find the position when the chain is tightest.

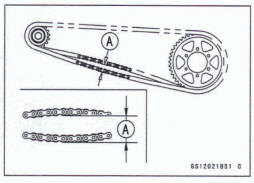

- Measure the vertical movement (chain slack) [A] midway between the sprockets.

*If the chain slack exceeds the standard, adjust it

Chain Slack Standard: 20 - 30 mm (0.8 - 1.2 in.)

Drive Chain Slack Adjustment

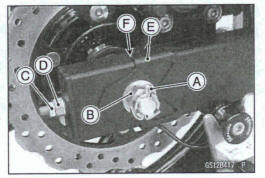

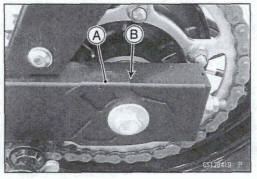

- Remove the cotter pin [A], and loosen the axle nut [B].

- Loosen the both chain adjuster locknuts [C].

If the chain is too loose, turn in the left and right chair adjusters [D] evenly

If the chain is too tight, turn out the left and right chain adjusters evenly, and kick the wheel forward.

- Turn both chain adjusters evenly until the drive chain has the correct amount of slack. To keep the chain and wheel properly aligned, the right wheel alignment indicator [E] should align with the same swingarm mark or position [F] that the left indicator notch aligns with.

Misalignment of the wheel will result in abnormal wear and may result in an unsafe riding condition.

Be sure the wheel is properly aligned.

- Tighten both chain adjuster locknuts securely.

- Tighten: Toque - Rear Axle Nut: 98 N-m (10 k*m, 72 ft*lb)

- Turn the wheel, measure the chain slack again at the tightest position, and readjust if necessary

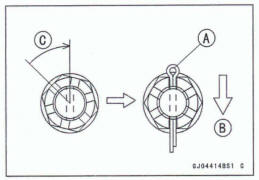

- Insert a new cotter pin [A] downward [B].

NOTE

- When inserting the cotter pin, if the dots in the nut do not align with the cotter pin hole in the axle, tighten the nut clockwise [C] up to next alignment.

- It should be within 30 degrees.

- Loosen once end tighten again when the slot goes past the nearest hole.

- Bend the cotter pin [A] along the nut [B].

WARNING

A loose axle nut can lead to an accident resulting in serious injury or death. Tighten the axle nut to the proper toque and install a new cotter pin.

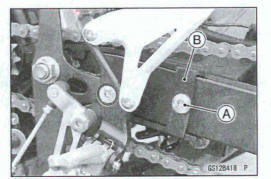

Wheel Alignment Inspection

Check that the left alignment indicator [A] aligns with the same swingarm mark or position [B] that the right alignment indicator notch aligns with.

If they do not, adjust the chain slack and aligns the wheel alignment (see Drive Chain Slack Adjustment).

NOTE

Wheel alignment can be also checked using the straightedge or string method.

WARNING

Misalignment of the wheel will result in abnormal wear and may result in unsafe riding condition. Be sure the wheel is properly aligned.

Drive Chain Wear Inspection

- Remove the mud guard (see Mud Guard Removal in the Frame chapter).

- Rotate the rear wheel to inspect the drive chain for damaged rollers, and loose pins and links.

If there is any irregularity, replace the drive chain.

Lubricate the drive chain if it appears dry.

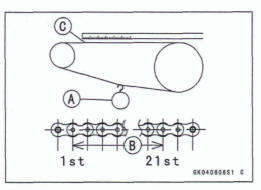

- Stretch the chain taut by hanging a 10 kg (22 lb) weight [A] on the chain.

- Measure the length of 20 links [B] on the straight part [C] of the chain from the pin center of the 1st pin to the pin center of the 21st pin. Since the chain may wear unevenly, take measurements at several places.

If any measurements exceed the service limit, replace the chain. Also, replace the front and rear sprockets when the drive chain is replaced.

Drive Chain 20-link Length

Standard: 317.5 - 318.2 mm (12.50 - 12.53 in.)

Service Limit: 319 mm (12.6 in.)

WARNING

A chain that breaks or Jumps off the sprockets could snag on the engine sprocket or lock the rear wheel, severely damaging the motorcycle and causing it to go out of control. Inspect the chain for damage and proper adjustment Mom each ride.

If chain wear exceed the service limit, replace it with the standard chain. It is an endless type and should not be cut for installation.

Standard Chain

Make: ENUMA

TYPE:

KS2OSR02

EK520LV03 (when shipping)

Link:106 links

Chain Gulde Wear Inspection

- Remove:

Mud Guard (see Mud Guard Removal in the Frame chapter)

Engine Sprocket Cover (see Engine Sprocket Removal in the Final drive chapter)

Bolt [A]

Chain Guide [B]

- Visually inspect the chain guide

If it shows any signs of abnormal wear or damage, replace the chain guide.

- Install the chain guide, and tighten its bolt.

See also:

Kawasaki Z400 - Service manual > Wheels/Tires

Kawasaki Z400 - Service manual > Wheels/Tires

Air Pressure Inspection Remove the air valve cap. Measure the tire air pressure with an air pressure gauge [A] when the tires are cold (that is, when the motorcycle has not been ridden more than a mile during the past 3 hours)

Kawasaki Z400 - Service manual > Brakes

Kawasaki Z400 - Service manual > Brakes

Brake System Inspection Brake Fluid Leak (Brake Hose and Pipe) Inspection For ABS equipped models, remove the air cleaner housing (see Air Cleaner Housing Removal in the Fuel System (DFI) chapter). Apply the brake lever or pedal and inspect the brake fluid leak from the brake hoses [A], fittings [B] and pipes [C] (ABS equipped models).

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03