Kawasaki Z400 - Service manual > Sprocket, Coupling

Kawasaki Z400 - Service manual > Sprocket, Coupling

Engine Sprocket Removal

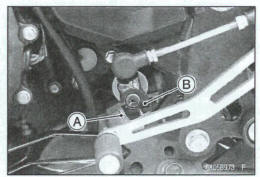

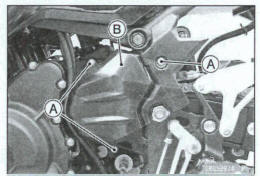

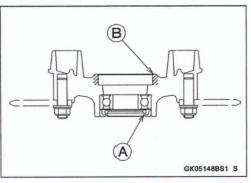

- Remove: Shift Lever Clamp Bolt [A] Shift Lever [B]

- Remove: Engine Sprocket Cover Bolts [A] Engine Sprocket Cover [B]

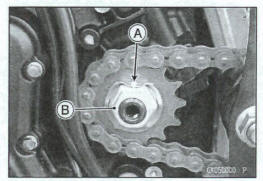

- Flatten out the bended washer [A].

- Remove the engine sprocket nut [B] and washer.

NOTE

When loosening the engine sprocket nut, hold the rear brake on.

- Mi the rear wheel off the ground with the stand.

- Loosen the drive chain (see Drive Chain Slack Adjustment in the Periodic Maintenance chapter).

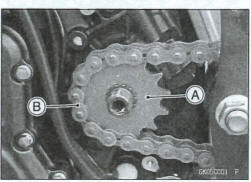

- Pull the engine sprocket [A] with drive chain [B] off the output shaft.

- Disengage the drive chain from the engine sprocket

Engine Sprocket Installation

- Replace the sprocket washer and axle cotter pin.

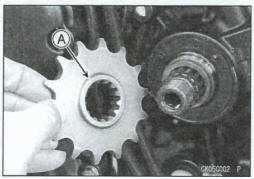

- Install the engine sprocket so that protruding side [A] faces inside.

- Apply molybdenum disulfide oil solution to the threads of output shaft and the surface of washer.

- Tighten: Torque - Engine Sprocket Nut: 127 N-m (13.0 kgf*m, 93.7 ft*lb)

NOTE

Tighten the nut while applying the rear brake.

- Bend the one side of the washer over the nut.

- Install the engine sprocket cover.

- Tighten:

Toque - Engine Sprocket Cover Bolts: 9.8 N-m (1.0 k*m, 87 in-lb)

- Adjust the drive chain slack after installing the engine sprocket (see Drive Chain Slack Adjustment in the Periodic Maintenance chapter).

- Install the removed parts (see appropriate chapters).

Rear Sprocket Removal

Remove the mar wheel (see Rear Wheel Removal in the Wheels/Tires chapter)

NOTICE

Do not lay the wheel on the ground with the disc facing down. This cm dame or warp the disc.

Place blocks under the wheel so that the disc does not touch the ground.

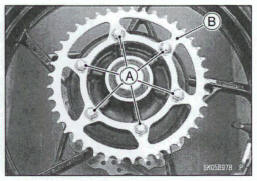

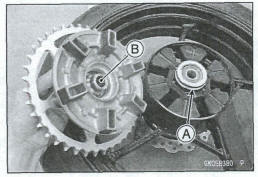

- Remove: Rear Sprocket Nuts [A] Rear Sprocket [B]

Rear Sprocket Installation

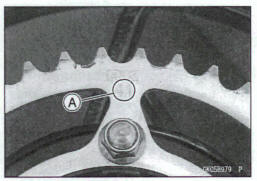

- Install the sprocket Facing the tooth number marking [A] outward.

- Replace the rear sprocket nub with new ones.

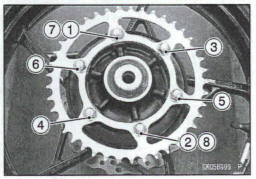

- Tighten the mar sprocket nuts following the specified tightening sequence [1 ~ 8].

Torque - Rear Sprocket Nuts: 58 N*m (6.0 kgf*m, 11 ff-lb)

- Install the rear wheel (see Rear Wheel Installation in the, wheels/tires chapter).

Coupling Installation

- Apply grease to the following.

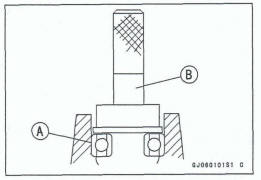

Coupling Grease Seal Lips [A] Coupling Internal Surface [B]

- Replace the O-ring [A] with a new one and apply grease to it.

- Install: O-ring Collar [B] Coupling

Coupling Bearing Removal

- Remove: Coupling Grease Seal

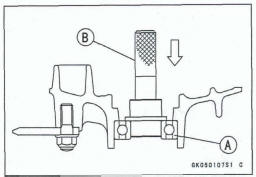

- Remove the bearing [A] by tapping from the wheel side.

Special Tool - Bearing Driver Set [B]: 57001-1129

Coupling Bearing Installation

- Replace the bearing with a new one.

NOTE

Install the coupling bearing with the mark faces outside.

- Press in the bearing [A] until it is bottomed.

Special Tool - Bearing Driver Set [B]: 57001-1129

Pack the bearing with high-temperature grease.

- Replace the grease seal with a new one.

- Press in the grease seal so that the seal surface is flush

with the end of the hole.

Apply high-temperature grease to the grease seal lips.

Special Tool - Bearing Driver Set: 57001 -1129

Coupling Bearing Inspection

Since the coupling bearing is made to extremely close tolerances, the clearance can not normally be measured.

NOTE

It is not necessary to remove the coupling bearing for inspection. If the bearing is removed, it will need to be replaced with a new one.

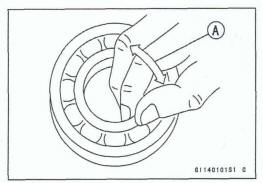

- Turn the bearing in the coupling back and forth [A] while checking for plays, roughness or binding

*If the bearing play, roughness or binding is found, replace the bearing.

Coupling Bearing Lubrication

- Pack the bearing with grease. Turn the bearing around by hand a few times to make sure the grease is distributed uniformly inside the bearing

Coupling Damper inspection

- Remove the rear wheel coupling, and inspect the rubber dampers [A].

- Replace the damper if it appears damaged or deteriorated.

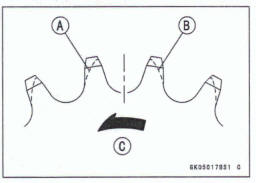

Sprocket War Inspection

- Visually inspect the engine and rear sprocket teeth for wear and damage

*If the teeth are worn as illustrated, replace the sprocket, and inspect the drive chain wear (see Drive Chain Wear Inspection in the Periodic Maintenance chapter).

Worn Tooth (Engine Sprocket) [A]

Worn Tooth (Rear Sprocket) [B]

Direction of Rotation [C]

NOTE

If a sprocket requires replacement, the chain is probably worn also. When replacing a sprocket, inspect the chain.

Rear Sprocket Warp Inspection

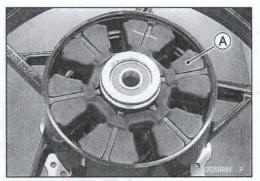

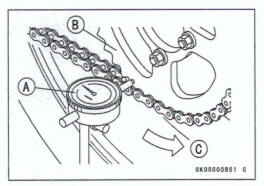

- Raise the rear wheel off the ground with the stand so that it will turn freely.

- Set a dial gauge [A] against the mar sprocket [B] near the teeth as shown, and rotate [C] the rear wheel to measure the sprocket runout (warp). The difference between the highest and lowest dial gauge readings is the amount of runout (warp)

*If the runout exceeds the service limit, replace the rear sprocket.

Rear Sprocket Warp

Standard: TIR 0.4 mm (0.016 in.) or lass

Service Limit: TIR 0.5 mm (0.020 in.)

See also:

Kawasaki Z400 - Service manual > Drive Chain

Kawasaki Z400 - Service manual > Drive Chain

Drive Chain Slack Inspection Refer to the Drive Chain Slack Inspection in the Periodic Maintenance chapter. Drive Chain Slack Adjustment Refer to the Drive Chain Slack Adjustment in the Periodic Maintenance chapter.

Kawasaki Z400 - Service manual > Brakes

Kawasaki Z400 - Service manual > Brakes

Exploded View

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03