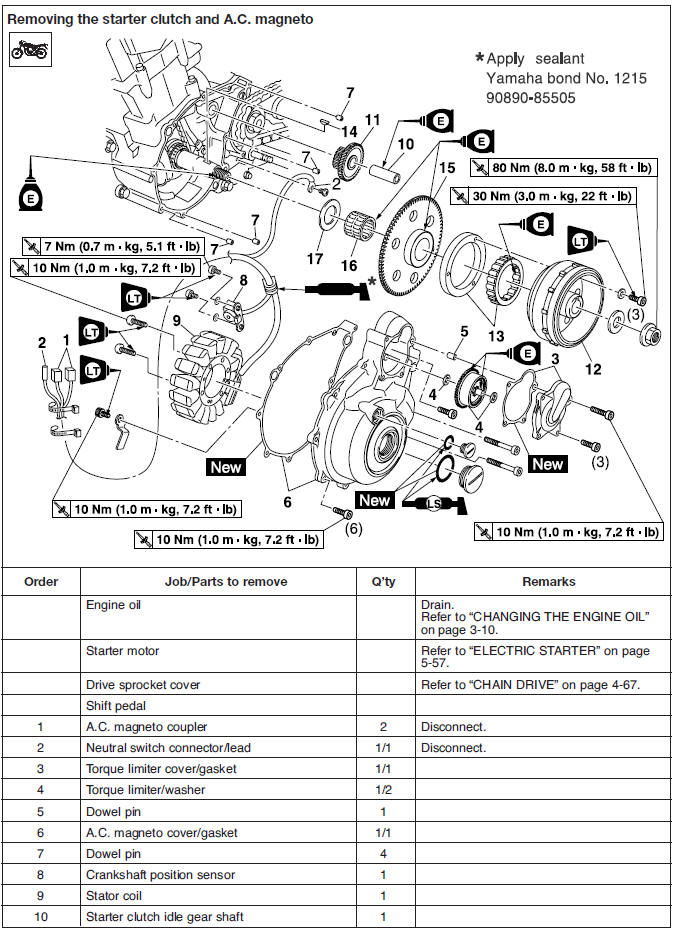

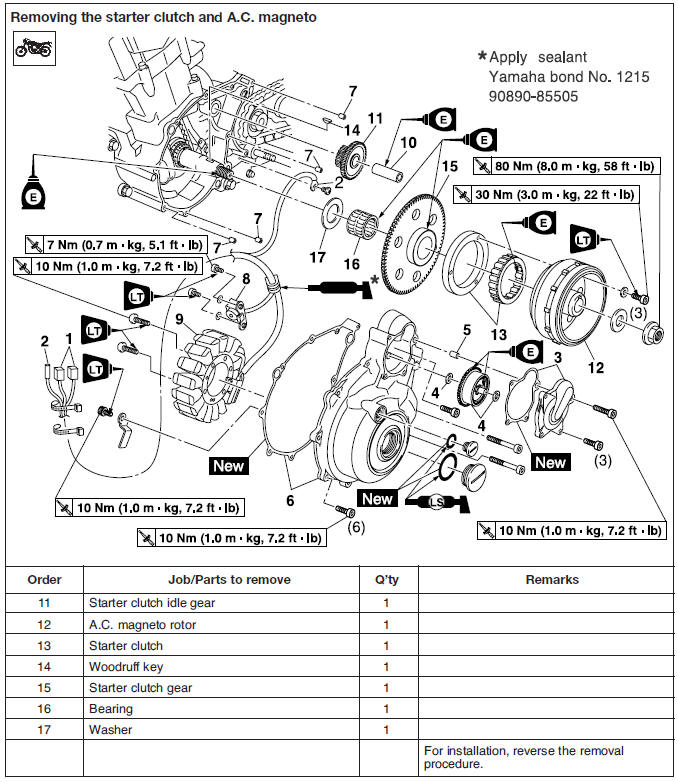

Yamaha MT-03 - Service manual > Starter clutch and A.C. Magneto

Yamaha MT-03 - Service manual > Starter clutch and A.C. Magneto

Removing the A.C. Magneto rotor

1. Remove:

- Torque limiter cover

CAUTION:

Do not remove the bearing "1".

2. Remove:

- A.C. magneto cover

NOTE:

Loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them.

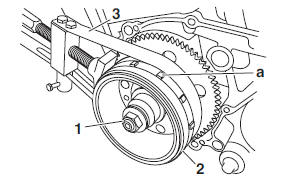

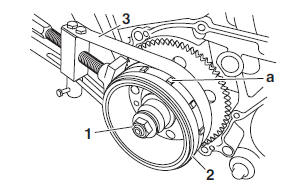

3. Remove:

- A.C. magneto rotor nut "1"

- Washer

NOTE:

- While holding the A.C. magneto rotor "2" with the sheave holder "3", loosen the A.C. magneto rotor nut.

- Do not allow the sheave holder to touch the projection "a" on the A.C. magneto rotor.

Sheave holder

90890-01701

Sheave holder

90890-01701

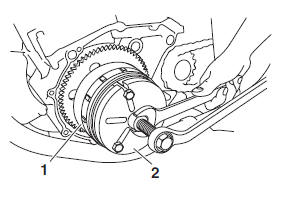

4. Remove:

- A.C. magneto rotor "1" (with the flywheel puller "2")

- Woodruff key

NOTE:

Use the rotor puller.

Flywheel puller

90890-01362

Flywheel puller

90890-01362

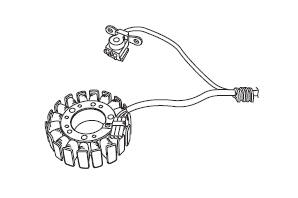

Checking the stator coil and crankshaft Position sensor

1. Check:

- Stator coil

- Crankshaft position sensor

Damage → Replace the crankshaft position sensor/stator assembly.

Checking the starter clutch

1. Check:

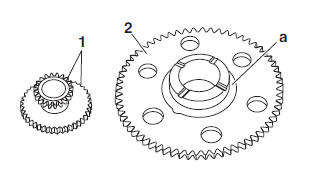

- Starter clutch rollers "1" Damage/wear → Replace.

2. Check:

- Starter clutch idle gear "1"

- Starter clutch gear "2" Burrs/chips/roughness/wear → Replace the defective part(s).

3. Check:

- Starter clutch gear's contacting surfaces "a" Damage/pitting/wear → Replace the starter clutch gear.

4. Check:

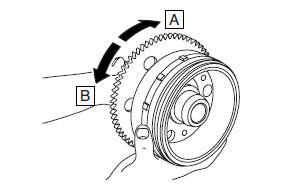

- Starter clutch operation

a. Install the starter clutch gear onto the starter clutch and hold the starter clutch.

b. When turning the starter clutch gear clock wise

, it should turn freely, otherwise

the

starter clutch is faulty and must be replaced.

, it should turn freely, otherwise

the

starter clutch is faulty and must be replaced.

c. When turning the starter clutch gear counter clock wise

, the starter clutch and the

starter clutch gear should engage, otherwise

the starter clutch is faulty and must be

replaced.

, the starter clutch and the

starter clutch gear should engage, otherwise

the starter clutch is faulty and must be

replaced.

Checking the torque limiter

1. Check:

- Torque limiter Damage/wear → Replace.

Installing the A.C. Magneto rotor

1. Install:

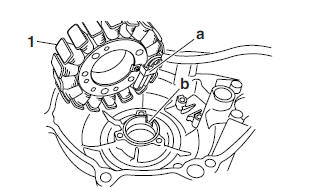

- Stator coil "1"

Stator coil bolts

10 Nm (1.0 m*kg, 7.2 ft*lb)

LOCTITE

Stator coil bolts

10 Nm (1.0 m*kg, 7.2 ft*lb)

LOCTITE

- Crankshaft position sensor

Crankshaft position sensor

bolts

7 Nm (0.7 m*kg, 5.1 ft*lb)

LOCTITE

Crankshaft position sensor

bolts

7 Nm (0.7 m*kg, 5.1 ft*lb)

LOCTITE

NOTE:

Align the projection "a" on the stator coil with the slot "b" in the A.C. magneto cover.

2. Apply:

- Yamaha bond No. 1215 "1" (into the slits)

Yamaha bond No. 1215

90890-85505

Yamaha bond No. 1215

90890-85505

3. Install:

- Starter clutch "1" (to A.C. magneto rotor)

- Starter clutch bolts

Starter clutch bolts

30 Nm (3.0 m*kg, 22 ft*lb)

LOCTITE

Starter clutch bolts

30 Nm (3.0 m*kg, 22 ft*lb)

LOCTITE

4. Install:

- Woodruff key

- A.C. magneto rotor

- Washer

- A.C. magneto rotor nut

NOTE:

- Clean the tapered portion of the crankshaft and the A.C. magneto rotor hub.

- When installing the A.C. magneto rotor, make sure the woodruff key is properly seated in the keyway of the crankshaft.

- Lubricate crankshaft end threads with engine oil.

5. Tighten:

- A.C. magneto rotor nut "1"

A.C. magneto rotor nut

80 Nm (8.0 m*kg, 58 ft*lb)

A.C. magneto rotor nut

80 Nm (8.0 m*kg, 58 ft*lb)

NOTE:

- While holding the A.C. magneto rotor "2" with the sheave holder "3", tighten the A.C. magneto rotor nut.

- Do not allow the sheave holder to touch the projection "a" on the A.C. magneto rotor.

Sheave holder

90890-01701

Sheave holder

90890-01701

6. Install:

- Gasket

- A.C. magneto cover

A.C. magneto cover bolts

10 Nm (1.0 m*kg, 7.2 ft*lb)

LOCTITE

A.C. magneto cover bolts

10 Nm (1.0 m*kg, 7.2 ft*lb)

LOCTITE

NOTE:

Tighten the A.C. magneto cover bolts in stages, using a crisscross pattern.

7. Install:

- Neutral switch lead "1"

NOTE:

Route the neutral switch lead so that it is taut and route it under the speed sensor lead "2" as shown.

a. 5 mm or more

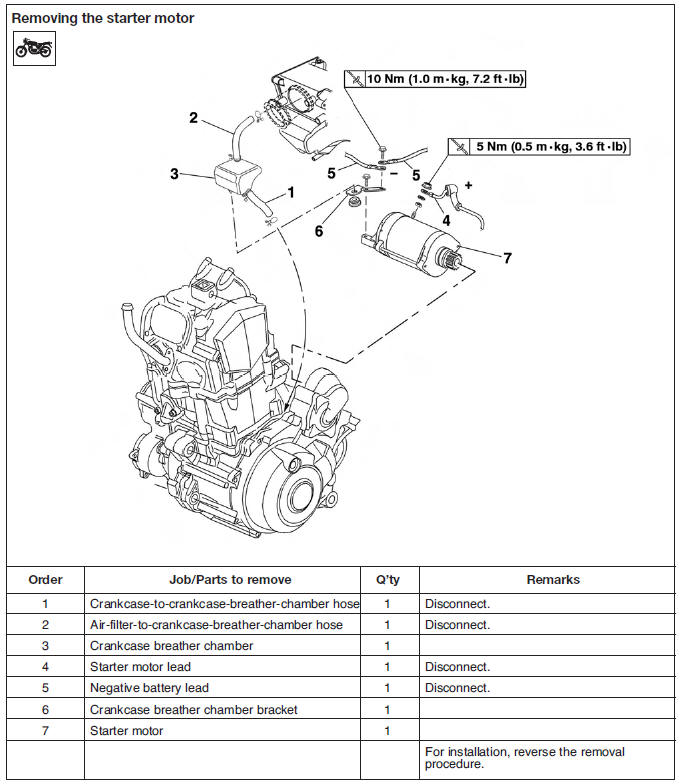

Electric starter

Checking the starter motor

1. Check:

- Commutator

Dirt → Clean with 600 grit sandpaper.

2. Measure:

- Commutator diameter "a"

Out of specification → Replace the starter motor.

Limit

27.0 mm (1.06 in)

Limit

27.0 mm (1.06 in)

3. Measure:

- Mica undercut "a"

Out of specification → Scrape the mica to the proper measurement with a hacksaw blade that has been grounded to fit the commutator.

Mica undercut (depth)

0.70 mm (0.028 in)

Mica undercut (depth)

0.70 mm (0.028 in)

NOTE:

The mica of the commutator must be undercut to ensure proper operation of the commutator.

4. Measure:

- Armature assembly resistances (commutator and insulation) Out of specification → Replace the starter motor.

a. Measure the armature assembly resistances with the pocket tester.

Pocket tester

90890-03112

Pocket tester

90890-03112

Armature coil

Commutator resistance "1"

0.025-0.035 Ω at 20ºC (68ºF)

Armature coil

Commutator resistance "1"

0.025-0.035 Ω at 20ºC (68ºF)

Insulation resistance "2" Above 1 M at 20ºC (68ºF)

b. If any resistance is out of specification, replace the starter motor.

5. Measure:

- Brush length "a"

Out of specification → Replace the brushes as a set.

Limit

5.00 mm (0.20 in)

Limit

5.00 mm (0.20 in)

6. Measure:

- Brush spring force

Out of specification → Replace the brush springs as a set.

Brush spring force

7.65-10.01 N (27.51-36.01 oz)

(780-1,021 gf)

Brush spring force

7.65-10.01 N (27.51-36.01 oz)

(780-1,021 gf)

7. Check:

- Gear teeth.

Damage/wear → Replace the gear.

8. Check:

- Bearing

- Oil seal

Damage/wear →Replace the defective part(s).

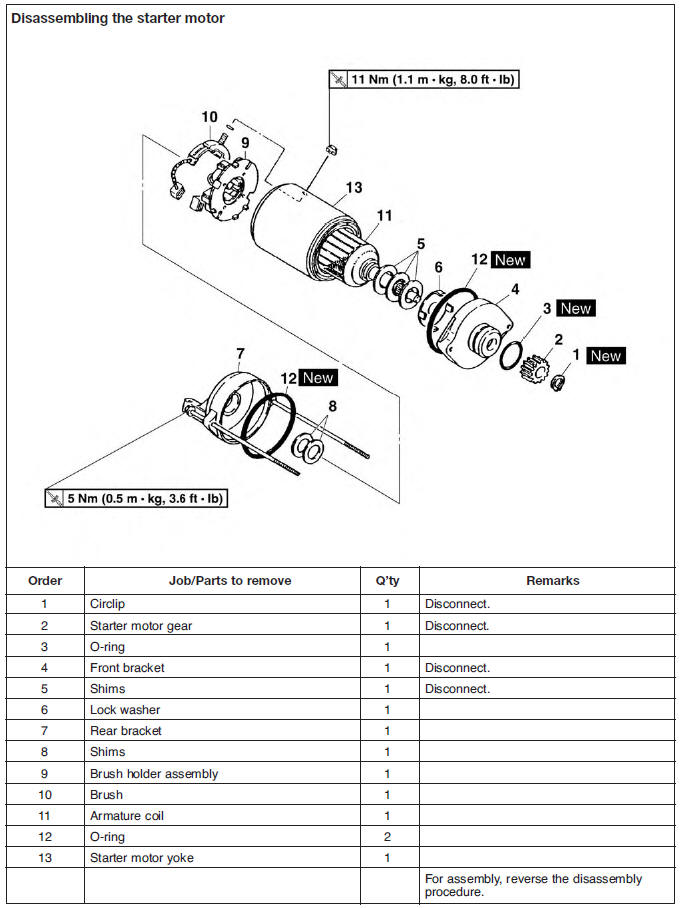

Assembling the starter motor

1. Install:

- Brush seat "1"

NOTE:

Align the tab "a" on the brush seat with the slot "b" in the starter motor yoke.

2. Install:

- Lock washer

NOTE:

Align the tabs "a" on the lock washer with the groves in the front bracket.

3. Install:

- Rear bracket

NOTE:

Align the slot "a" in the rear bracket with the tab "b" on the brush seat.

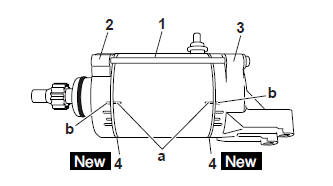

4. Install

- Starter motor yoke "1"

- Front bracket "2"

- Rear bracket "3"

- O-rings "4"

- Bolts

Starter motor bracket bolts

5 Nm (0.5 m*kg, 3.6 ft*lb)

Starter motor bracket bolts

5 Nm (0.5 m*kg, 3.6 ft*lb)

NOTE:

Align the alignment marks "a" on the starter motor yoke with the alignment marks "b" on the front and rear brackets.

5. Install:

- Starter motor gear

- Circlip

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03