Kawasaki Z400 - Service manual > Fuel Tank

Kawasaki Z400 - Service manual > Fuel Tank

Fuel Tank Removal

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions, creating the potential for serious bums. Make sum the area Is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the ignition switch off. Disconnect the battery (-)terminal. To avoid fuel spills, draw it from the tank when the engine b cold. E4a prepared for fuel spillage; any spilled fuel must be completely wiped up immediately.

- Turn the ignition switch off.

- Wait until the engine cools down.

- Disconnect the battery (-) terminal (see Battery Removal in the Electrical System chapter).

- Remove: Seats (Rear/Front Seat Removal in the Frame chapter) Middle Fairings (see Middle Fairing Removal in the Frame chapter)

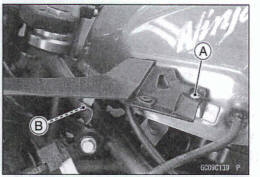

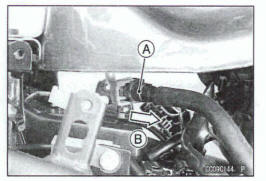

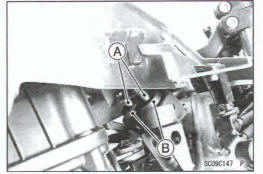

- Remove the bolt [A] on both sides.

- Clear the projection [B] of the upper inner fairing to the grommet on both sides.

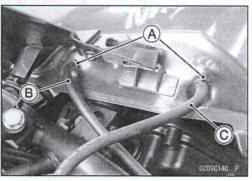

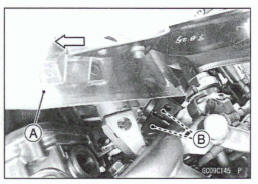

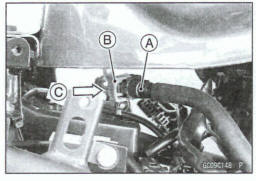

- Slide the damps [A].

- Disconnect: Drain Hose [B] Breather Hose [C]

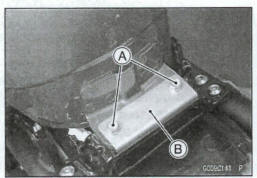

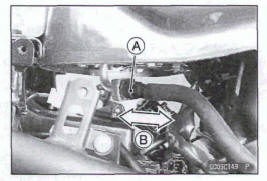

- Remove: Fuel Tank Bolts [A] Bracket [B]

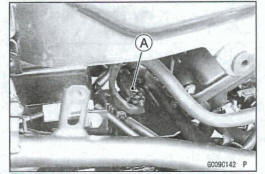

- Disconnect the fuel pump lead connector [A].

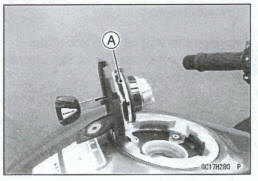

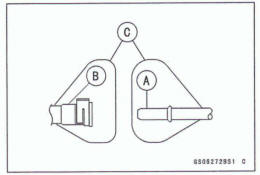

- Open the fuel tank cap [A] to lower the pressure In the tank.

- During tank removal, keep the tank cap open to release pressure in the tank. This makes fuel spillage less.

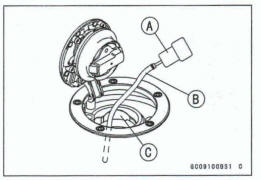

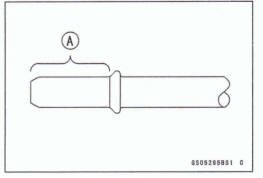

- Draw the fuel out from the fuel tank with a commercially available pump [A].

Use a soft plastic hose [B] as a pump intake hose in order to insert the hose smoothly.

Put the hose through the fill opening [C] into the tank and draw the fuel out.

Warning

Spilled fuel is flammable and can be explosive under certain conditions. The fuel can not be removed completely from the fuel tank. Be careful for remained fuel spillage.

- Close be fuel tank cap.

- Pull up the rear of the fuel tank.

- Be sure to place a piece of cloth around the fuel hose joint.

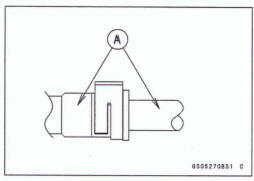

- Wipe off the dirt of the surface [A] around the connection using a cloth or a soft brush.

When removing with flat tip screwdriver

- Insert the flat tip screwdriver [A] into slit on the joint lock PI.

- Turn the driver to disconnect the joint lock

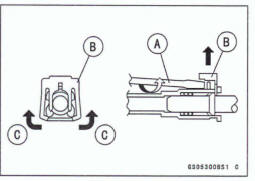

When removing with fingers

- Open and push up [C] the joint lock with your fingers

NOTICE

Prying or excessively widening the joint lock ends for fuel hose removal will permanently deform the joint lock, resulting in a loose or incomplete lock that may allow fuel to leak and create the potentla1 for a fire explosion. To prevent fir, or explosion from a damaged )old I- do not pry or exess6hnly widen the Join? lack ends when removing the fuel hose. The joint lock has a retaining edge that locks around the housing.

- Pull [A] the fuel hose joint [B] out of the outlet pipe.

WARNING

Fuel is flammable and explosive under certain conditions and can cause seven burns. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately. When the fuel hose Is disconnected, fuel spills out from the hose and the pipe because of residual pressure. Cover the hose connection with a piece of clean cloth to prevent fuel spillage.

- Remove the fuel tank [A] rearward to clear the projection [B] from the damper, and place it on a flat surface

Do not apply the load to the fuel pipe of the fuel pump.

- Clean the pipe [A].

- Cover the pipe and the hose joint [B] with the vinyl bags [C] to keep it clean.

Fuel Tank Installation

- Note the above WARNING (see Fuel Tank Removal).

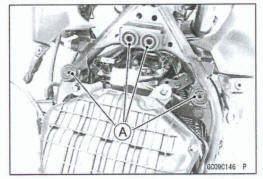

- Check that the dampers [A] are in place on the frame.

*If the dampers are damaged or deteriorated, replace them.

- Run the hoses correctly (see Cable, Wire, and Hose Routing section in the Appendix chapter).

- Insert the projections [A] of the fuel tank to the dampers PI.

- Remove the vinyl bag on the pipe and fuel hose joint.

- Check the joint lock for deformation and wear.

*If the joint lock is deformed, replace the fuel hose with a new one.

- Check that them are no flaws, bum, and adhesion of foreign materials on the pipe [A].

- Apply engine ail to the pipe.

- Insert the fuel hose joint [A] straight onto the fuel outlet pipe until the hose joint clicks.

- Push the joint lock [C] until the hose joint clicks.

- Push and pull [A] the hose joint [B] back and forth more than two times, and make sure it Is locked and does not come off.

- Connect the fuel pump lead connector and the battery (-) terminal (see Battery Installation In the Electrical System chapter).

- Install the removed parts (!me appropriate chapters).

- Tighten: Toque - Fuel Tank Bolts: 8.8 N-m (0.90 kgf-m, 78 In-lb)

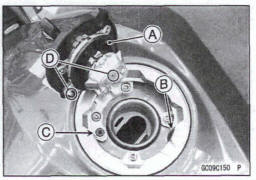

Fuel Tank and Cap Inspection

- Open the tank cap.

- Visually inspect the gasket [A] on the tank cap for any damage.

*Replace the tank cap if gasket is damaged.

Check to see if the water drain pipe [B] and fuel breather pipe [C] in the tank are not dogged. Check the tank cap breather also.

*If they are dogged, remove the tank and drain it, and then blow the breather free with compressed air.

NOTICE

Do not apply compressed air to the air vent holes [D] In the tank cap. This could cause damage and clogging of the labyrinth in the cap.

Fuel Tank Cleaning

WARNING

Gasoline and low flash-point solvents can be flammable and/or explosive and cause severe burns. Clean the tank In a well-ventilated area, and take care that them are no sparks or flame anywhere near the working arm. Do not use gasoline or low flash-point solvents to clean the tank.

- Remove: Fuel Tank (see Fuel Tank Removal) Fuel Pump (we Fuel Pump Removal)

- Pour some high flash-point solvent into the fuel tank and shake the tank to remove dirt and fuel deposits.

- Draw the solvent out of the fuel tank.

- Dry the tank with compressed air.

- Install: Fuel Pump (see Fuel Pump Installation) Fuel Tank (see Fuel Tank Installation)

Evaporative Emission Control System (Equipped Models)

The Evaporative Emission Control System routes fuel vapors from the fuel system into the running engine or stores the vapors in a canister when the engine is stopped. Although no adjustments are required, a thorough visual inspection must be made at the intervals specified by the Periodic Maintenance Chart.

Parts Removal/Installation

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition switch off. Do not smoke. Make sure the area Is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light.

NOTICE

If gasoline, solvent, water or any other liquid enters the canister, the canister's vapor absorbing capacity is greatly reduced. If the canister does become contaminated, replace It with a new one.

Run the hoses correctly (see Cable, Wire, end Hose Routing section in the Appendix chapter). Make sure they do not get pinched or kinked.

Hose Inspection

- Refer to the Evaporative Emission Control System Inspection (Equipped Models) in the Periodic Maintenance chapter

Purge Valve Inspection

- Refer to the Purge Valve Inspection

Canister Inspection

- Refer to the Evaporative Emission Control System Inspection (Equipped Models) in the Periodic Maintenance chapter

See also:

Kawasaki Z400 - Service manual > Fuel Pump

Kawasaki Z400 - Service manual > Fuel Pump

Fuel Pump Removal WARNING Gasoline Is extremely flammable and can be explosive under certain conditions, creating the potential for serious burns. Make sure the area is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the Ignition switch off. Disconnect the battery (-) terminal. To avoid fuel spills, draw it from the tank when the engine Is cold. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately.

Kawasaki Z400 - Service manual > Cooling System

Kawasaki Z400 - Service manual > Cooling System

Exploded View

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03