Triumph Street Triple S - Service manual > Front Brake Pads

Triumph Street Triple S - Service manual > Front Brake Pads

Front Brake Pads - Daytona 675 up to VIN 381274 and Street Triple R

Removal

Warning: Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

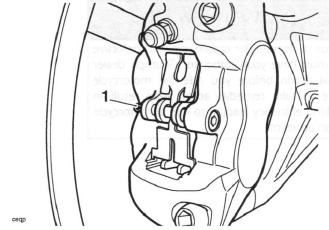

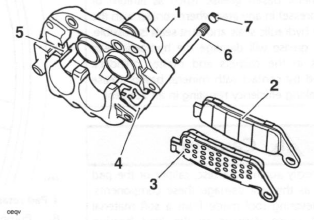

1. Remove the brake pad retaining pin after removing the 'R' clip from its inner end. Inspect the pad retaining pin for damage.

- 'R' clip

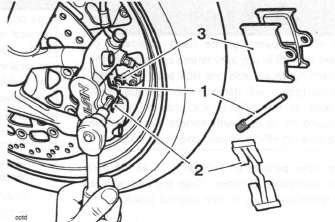

2. Remove the anti-rattle spring and inspect the spring for damage.

Caution: Never lever directly against the disc, caliper or the pad lining material as this will damage these components.

Always use a levering tool made from a soft material which will not cause damage to the load bearing surfaces.

Brake fluid will be displaced as the caliper pistons are compressed. To prevent body damage, ensure that the displaced fluid does not come into contact with any part of the bodywork.

3. Ease the brake pads apart to force the caliper pistons back to allow withdrawal of the pads.

4. Remove both brake pads and inspect for damage and wear beyond the service limit.

- Retaining pin

- Anti- rattle spring

- Brake pads

Note:

- Complete the assembly of the brake pads to one caliper (see assembly for details) before removing the pads from the other caliper.

Inspection

1. Check the 'R' clip, anti-rattle spring and retaining pin.

Renew any component which shows signs of damage or corrosion.

2. Check there is no sign of leakage from the piston seals. Rectify any problems before installing the pads.

Note:

- Complete the assembly of the brake pads to one caliper (see assembly for details) before removing the pads from the other caliper.

Installation

Warning: Never use mineral based grease (such as lithium or copper based grease) in any area where contact with the braking system hydraulic seals and dust seals is possible.

Mineral based grease will damage the hydraulic seals and dust seals in the calipers and master cylinders.

Damage caused by contact with mineral based grease may reduce braking efficiency resulting in an accident.

1. Fit new brake pads as an axle set or, if all the pads are in a serviceable condition, clean the pad grooves before refitting all pads in their original positions.

Warning: Do not apply more than a minimum coating of grease to the pad retaining pins. Excess grease may contaminate the brake pads, hydraulic seals and discs causing reduced braking efficiency and an accident.

2. Lubricate the pad retaining pin using a minimum amount of proprietary high temperature 'Copperslip' type grease.

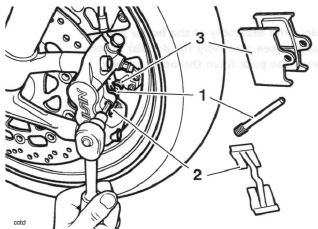

3. Fit the anti-rattle spring over the pads and push down in the centre to allow the pad retaining pin to slide across the top of the spring.

4. Tighten the pad retaining pin to 18 Nm, and secure with the 'R' clip.

- Retaining pin

- Anti-rattle spring

- Brake pads

5. Pump the brake lever to correctly position the caliper pistons.

6. Repeat the removal, inspection and installation process for the other caliper.

Warning: Use only DOT 4 specification brake fluid as listed in the general information section of this manual. The use of brake fluids other than those DOT 4 fluids listed in the general information section may reduce the efficiency of the braking system leading to loss of motorcycle control and an accident.

Observe the brake fluid handling warnings given earlier in this section of the manual.

7. Check the front brake fluid level and top up as required with new DOT 4 fluid.

8. Check for correct brake operation. Rectify as necessary.

Warning: It is dangerous to operate the motorcycle with defective brakes; you must have your authorised Triumph dealer take remedial action before you ride the motorcycle again. Failure to take remedial action may result in reduced braking efficiency leading to loss of motorcycle control and an accident.

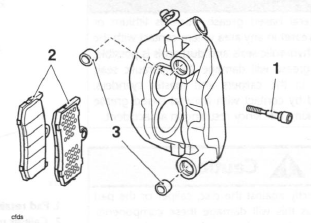

Front Brake Pads - Daytona 675 from VIN 381275

Removal

Warning: Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

Warning: Do not allow the calipers to hang on the brake hoses as this may damage the hoses and could lead to loss of motorcycle control and an accident.

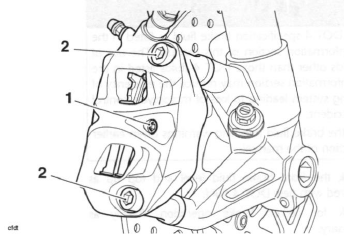

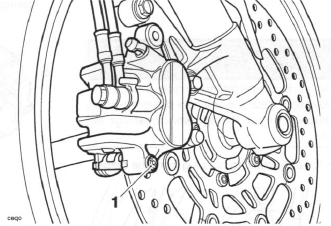

1. Loosen the pad retaining pin, remove the caliper mounting bolts and slide the caliper off the disc.

Recover the two dowels.

- Pad retaining pin

- Caliper mounting bolts

2. Remove the pad retaining pin and remove the pads from the caliper. Take care not to lose the anti-rattle spring from the caliper body.

- Pad retaining pin

- Brake pads

- Dowels

Inspection

1. Check the anti-rattle spring and retaining pin. Renew any component which shows signs of damage or corrosion.

2. Check there is no sign of leakage from the piston seals. Rectify any problems before installing the pads.

Note:

- Complete the assembly of the brake pads to one caliper (see assembly for details) before removing the pads from the other caliper.

Installation

Warning: Never use mineral based grease (such as lithium or copper based grease) in any area where contact with the braking system hydraulic seals and dust seals is possible.

Mineral based grease will damage the hydraulic seals and dust seals in the calipers and master cylinders.

Damage caused by contact with mineral based grease may reduce braking efficiency resulting in an accident.

Caution: Never lever directly against the disc, caliper or the pad lining material as this will damage these components.

Always use a levering tool made from a soft material which will not cause damage to the load bearing surfaces.

Brake fluid will be displaced as the caliper pistons are compressed. To prevent body damage, ensure that the displaced fluid does not come into contact with any part of the bodywork.

1. If new pads are being installed, push the pistons fully back into the caliper body. Keep an eye on the fluid level in the reservoir whilst retracting the pistons to prevent fluid spillage.

2. Ensure the anti-rattle spring is securely clipped onto the caliper body.

Warning: Do not apply more than a minimum coating of grease to the pad retaining pins. Excess grease may contaminate the brake pads, hydraulic seals and discs causing reduced braking efficiency and an accident.

3. Lubricate the pad retaining pin with a thin smear of proprietary high temperature 'Copperslip' type grease.

4. Ensure the heat isolation pads are fitted to the back of each brake pad. Fit the pads to the caliper with their friction material surfaces facing each other.

Locate the pad upper ends in the mounting bracket retainer then align them with the caliper body and insert the retaining pin.

5. Slide the caliper onto the disc, ensuring the pads pass either side, and fit the mounting bolts. Tighten the mounting bolts to 35 Nm.

6. Tighten the pad retaining pin to 18 Nm.

- Pad retaining pin

- Caliper mounting bolts

7. Pump the brake lever to correctly position the caliper pistons.

8. Repeat the removal, inspection and installation process for the other caliper.

Warning: Use only DOT 4 specification brake fluid as listed in the general information section of this manual. The use of brake fluids other than those DOT 4 fluids listed in the general information section may reduce the efficiency of the braking system leading to loss of motorcycle control and an accident.

Observe the brake fluid handling warnings given earlier in this section of the manual.

9. Check the front brake fluid level and top up as required with new DOT 4 fluid.

10. Check for correct brake operation. Rectify as necessary.

Warning: It is dangerous to operate the motorcycle with defective brakes; you must have your authorised Triumph dealer take remedial action before you ride the motorcycle again. Failure to take remedial action may result in reduced braking efficiency leading to loss of motorcycle control and an accident.

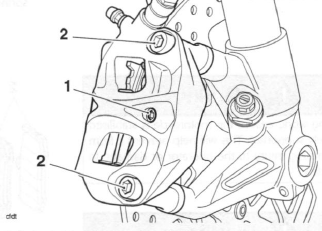

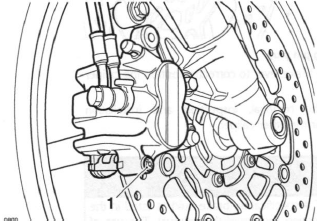

Front Brake Pads - Street Triple

Removal

Warning: Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

1. Unscrew the pad retaining pin plug from the caliper.

- Pad retaining pin plug

2. Loosen the pad retaining pin.

- Pad retaining pin

Warning: Do not allow the calipers to hang on the brake hoses as this may damage the hoses and could lead to loss of motorcycle control and an accident.

3. Slacken and remove the caliper mounting bolts and slide the caliper off the disc.

4. Remove the pad retaining pin and remove the pads from the caliper. Take care not to lose the pad retainer from the mounting bracket or the anti-rattle spring from the caliper body.

- Caliper

- Brake pad

- Heat isolation pad

- Anti-rattle spring

- Pad retainer

- Pad retaining pin

- Pad retaining pin plug

Inspection

1. Check the pad retainer, anti-rattle spring and retaining pin. Renew any component which shows signs of damage or corrosion.

2. Check the caliper body slides easily on the mounting bracket pins and check there is no sign of leakage from the piston seals. Rectify any problems before installing the pads.

Note:

- Complete the assembly of the brake pads to one caliper (see assembly for details) before removing the pads from the other caliper.

Installation

Warning: Never use mineral based grease (such as lithium or copper based grease) in any area where contact with the braking system hydraulic seals and dust seals is possible.

Mineral based grease will damage the hydraulic seals and dust seals in the calipers and master cylinders.

Damage caused by contact with mineral based grease may reduce braking efficiency resulting in an accident.

Caution: Never lever directly against the disc, caliper or the pad lining material as this will damage these components.

Always use a levering tool made from a soft material which will not cause damage to the load bearing surfaces.

Brake fluid will be displaced as the caliper pistons are compressed. To prevent body damage, ensure that the displaced fluid does not come into contact with any part of the bodywork.

1. If new pads are being installed, push the pistons fully back into the caliper body. Keep an eye on the fluid level in the reservoir whilst retracting the pistons to prevent fluid spillage.

2. Ensure the pad retainer is correctly fitted to the mounting bracket and the anti-rattle spring is securely clipped onto the caliper body.

Warning: Do not apply more than a minimum coating of grease to the pad retaining pins. Excess grease may contaminate the brake pads, hydraulic seals and discs causing reduced braking efficiency and an accident.

3. Lubricate the pad retaining pin with a thin smear of proprietary high temperature 'Copperslip' type grease.

4. Ensure the heat isolation pads are fitted to the back of each brake pad. Fit the pads to the caliper with their friction material surfaces facing each other.

Locate the pad upper ends in the mounting bracket retainer then align them with the caliper body and insert the retaining pin.

5. Slide the caliper onto the disc, ensuring the pads pass either side, and fit the mounting bolts. Tighten the mounting bolts to 28 Nm.

6. Tighten the pad retaining pin to 18 Nm.

7. Fit the pad retaining pin plug to the caliper and tighten to 3 Nm.

- Pad retaining pin plug

8. Pump the brake lever to correctly position the caliper pistons.

9. Repeat the removal, inspection and installation process for the other caliper.

Warning: Use only DOT 4 specification brake fluid as listed in the general information section of this manual. The use of brake fluids other than those DOT 4 fluids listed in the general information section may reduce the efficiency of the braking system leading to loss of motorcycle control and an accident.

Observe the brake fluid handling warnings given earlier in this section of the manual.

10. Check the front brake fluid level and top up as required with new DOT 4 fluid.

11. Check for correct brake operation. Rectify as necessary.

Warning: It is dangerous to operate the motorcycle with defective brakes; you must have your authorised Triumph dealer take remedial action before you ride the motorcycle again. Failure to take remedial action may result in reduced braking efficiency leading to loss of motorcycle control and an accident.

See also:

Triumph Street Triple S - Service manual > Braking System Maintenance Safety Precautions

Triumph Street Triple S - Service manual > Braking System Maintenance Safety Precautions

Warning: Brake fluid is hygroscopic which means it will absorb moisture from the air. The absorbed moisture will greatly reduce the boiling point of the brake fluid causing a reduction in braking efficiency.

Triumph Street Triple S - Service manual > Front Brake Caliper

Triumph Street Triple S - Service manual > Front Brake Caliper

Front Brake Caliper - Daytona 675 up to VIN 381274 and Street Triple R Removal Warning: Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03