Kawasaki Z400 - Service manual > ECU

Kawasaki Z400 - Service manual > ECU

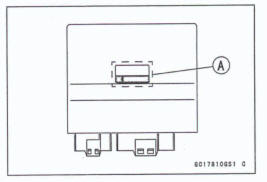

ECU Identification

Most countries have their own regulations, so each ECU has different characteristic. So, do not confuse ECU with each other and use only the ECU for your model. Otherwise, the motorcycle cannot clear the regulation.

ECU Identification

ECU Removal

NOTICE

Never drop the ECU especially on a hard surface.

Such a shock to the ECU can damage it.

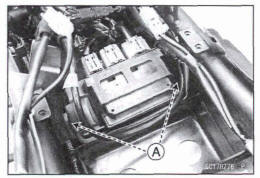

- Remove: Battery Case Cover (see Battery Case Cover Removal in the Frame chapter)

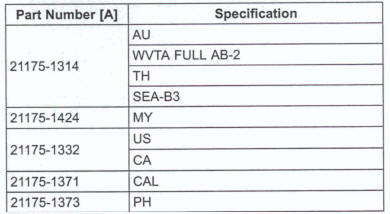

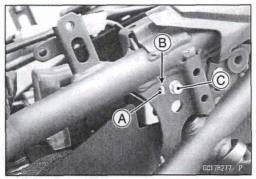

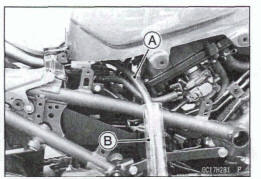

- Remove the bolt [A] and free the starter relay [B] from the frame.

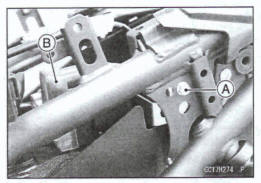

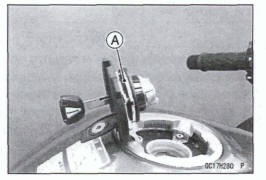

- Lift up the ECU [A ] with rubber protector to dear the projections [B].

- Disconnect:

Relay Box Connectors [C] ECU Connectors [Dl

- Remove the ECU from the rubber protector

ECU Installation

- Connect:

ECU Connectors

Relay Box Connectors

- Insert the slits of the rubber protector to the projections [A] of the battery case.

- Insert the projection [A] of the hole [B] of the frame.

- Tighten the bolt [C].

- Install the removed parts (see starter relay bracket to the appropriate chapters).

ECU Power Supply Inspection

- Remove the battery case cover (see Battery Case Cover Removal in the Frame chapter).

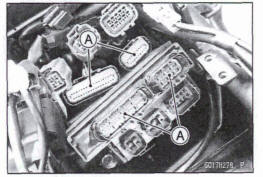

- Visually inspect the ECU connectors.

*If the connector is dogged with mud or dust, blow it off with compressed air.

- Remove the ECU (see ECU Removal).

- Visually inspect the terminals [A] of the ECU and main harness connectors.

*If the terminals of the main harness connectors are damaged, replace the main harness.

*If the terminals of the ECU connectors are damaged, replace the ECU.

- Turn the ignition switch off.

- Disconnect the ECU connectors [A].

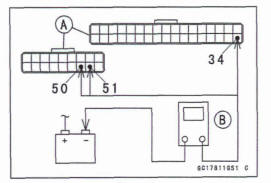

- Set a tester [B] and check the following wiring for continuity.

ECU Grounding Inspection Connections:

(I) ECU Terminal 50 or 51 ←→ Battery (-) Terminal

ECU Terminal 34

(11) Engine Ground ←→ Battery (-) Terminal

Criteria:

Both:

*If no continuity, check the connectors, the engine ground lead, or main harness, and repair or replace them if necessary.

*If the wiring is good, check the power source voltage of the ECU.

- Connect the ECU connectors.

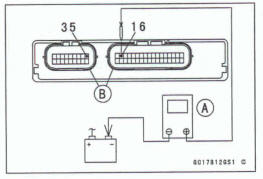

- Connect a digital meter [A] to the connectors [B] with the needle adapter set

Special Tool - Needle Adapter Set: 57001 -1874

ECU Power Supply Inspection Connections:

(I) Digital Meter (+) → Terminal 16 (BR/W)

Digital Meter (-) → Battery (-) Terminal

(11) Digital Meter (+) → Terminal 35 (W/BK)

Digital Meter (-) → Battery (-) Terminal

Ignition Switch off:

Terminal 16 (BR/W): 0 V

Terminal 35 (W/BK): Battery Voltage

Ignition Switch on:

Both: Battery Voltage

*If the reading is out of the specification, check the following.

Main Fuse 30 A (see Fuse Inspection in the Electrical System chapter)

ECU Fuse 15 A (see Fuse Inspection in the Electrical System chapter)

ECU Main Relay (see Relay Circuit Inspection in the Electrical System chapter)

Power Source Wiring (see ECU Power Source Circuit)

*If the fuse, wiring and relay are good, replace the ECU (see ECU Removal/Installation).

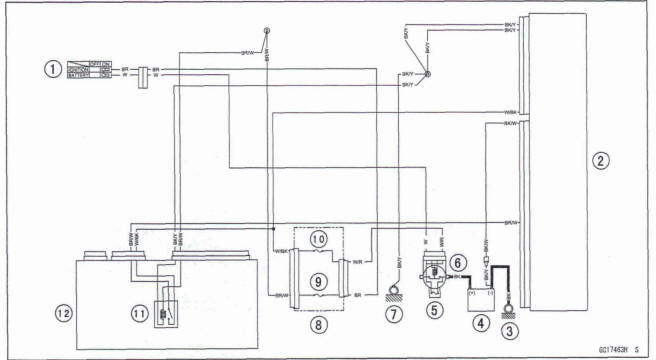

ECU Power Source Circuit

- Ignition Switch

- ECU

- Engine Ground

- Battery

- Main Fuse 30 A

- Starter Relay

- Frame Ground (2)

- Fuse Box (1)

- Ignition Fuse 10 A

- ECU Fuse 15 A

- ECU Main Relay

- Relay Box

DFI Power Source

ECU Fuse Removal

- Refer to the Fuse Box Fuse Removal in the Electrical System chapter.

ECU Fuse Installation

*If a fuse fails during operation, inspect the DFI system to determine the cause, and then replace it with a new fuse of proper amperage

- Refer to the Fuse Installation in the Electrical System chapter.

ECU Fuse Inspection

- Refer to the Fuse Inspection in the Electrical System chapter.

ECU Main Relay Removal/Installation

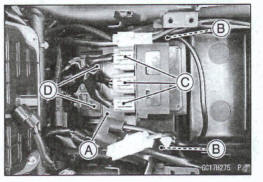

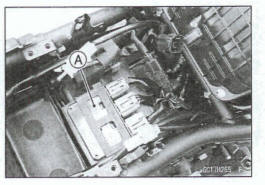

The ECU main relay is built in the relay box [A].

- Refer to the Relay Box Removal in the Electrical System chapter.

ECU Main Relay Inspection

- Refer to the Relay Circuit Inspection in the Electrical System chapter.

Fuel Line

Fuel Pressure Inspection

NOTE

- Be sum the battery is fully changed.

Remove: Fuel Hose (see Fuel Hose Replacement in the Periodic Maintenance chapter)

Be sure to place a piece of cloth around the fuel outlet pips of the fuel pump and the delivery pipe of the throttle body assy.

WARNING

Fuel is flammable and explosive under certain conditions and can cause severe burns. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately. When the fuel hose is disconnected, fuel spills out from the hose and the pipe because of residual pressure. Cover the hose connection with a piece of clean cloth to prevent fuel spillage.

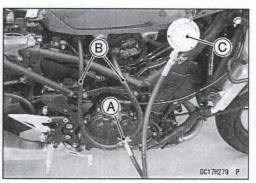

- Install the fuel pressure gauge adapter [A] and fuel hoses (Special Tool: 57001-1607) [B] between the fuel outlet pipe and delivery pipe.

- Secure the fuel hoses with the damps.

- Connect the pressure gauge [C] to the fuel pressure gauge adapter

WARNING

Fuel Is extremely flammable and can be explosive under certain conditions resulting in serious Injury or death. Do not try to start the engine with the fuel hoses disconnected.

- Connect the fuel pump lead connector.

- Turn the engine stop switch to run won.

- Turn the ignition switch on

The fuel pump should operate for 3 seconds, and then should stop.

NOTE

After turning on the engine stop switch and ignition switch, inspect the he! leakage from the connected portion of the special tools.

Notice

Do not drive the fuel pump 3 seconds or more without the fuel in the fuel tank. If the fuel pump is driven without the fuel, it may be damaged.

- Start the engine, and let it idle.

- Measure the fuel pressure with the engine idling.

Fuel Pressure (with Engine Idling) Standard: 294 kPa (3.0 kgf/cm2, 43 psi)

NOTE

The gauge needle will fluctuate. Read the pressure at the average of the maximum and minimum indications.

- Turn the ignition switch off

*If the fuel pressure is much higher than specified, replace the fuel pump because the fuel pressure regulator in the fuel pump have been clogged or stuck.

*If the fuel pressure is much lower than specified, check the following.

Fuel Line Leakage (see Fuel Injector Fuel Line Inspection) Amount of Fuel Flow (see Fuel Flow Rate Inspection)

- After above checks, measure the fuel pressure again.

- Remove the fuel pressure gauge, hoses and adapter.

- Install: Fuel Hose (see Fuel Hose Replacement in the Periodic Maintenance chapter)

- Start the engine and check for fuel leakage.

Fuel Row Rate Inspection

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions, creating the potential for serious bums. Make sure the area is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the ignition switch off. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately.

NOTE

Be sure the battery is fully charged.

- Turn the ignition switch off.

- Wait until the engine cools down.

- Prepare a fuel hose (Special Tool: 57001-1607) and a measuring cylinder

Special Tool - Fuel Hose: 57001-1607

- Open the fuel tank cap [A] to lower the pressure in the tank.

- Disconnect the fuel hose from the fuel pump (see Fuel Tank Removal).

Be sure to place a piece of cloth around the fuel outlet pipe of the fuel pump

WARNING

Fuel is flammable and explosive under certain conditions and can cause severe burns. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately. When the fuel hose is disconnected, fuel spills out from the hose and the pipe because of residual pressure. Cover the hose connection with a piece of clean cloth to prevent fuel spillage.

- Connect the prepared fuel ham [A] to the fuel outlet pipe.

- Secure the fuel hose with a clamp.

- Insert the fuel hose into the measuring cylinder [B]

Warning

Wipe off spilled out fuel immediately. Be sure to hold the measuring cylinder vertical.

- Close the fuel tank cap.

- Turn the engine stop switch to run position.

- Turn the ignition switch on.

The fuel pump should operate for 3 seconds, and then should stop.

Notice

Do not drive the fuel pump 3 seconds or more without the fuel in the fuel tank. If the fuel pump is driven without the fuel, it may be damaged.

- Install the fuel nose (sea Fuel Tank Installation).

- Start the engine and check for fuel leakage.

See also:

Kawasaki Z400 - Service manual > Purge Valve (Service Code 3A) (DTC P0443) (Equipped Models)

Kawasaki Z400 - Service manual > Purge Valve (Service Code 3A) (DTC P0443) (Equipped Models)

Purge Valve Removal/Installation Remove: Left Middle Fairing (see Middle Fairing Removal in the Frame chapter) Disconnect the purge valve connector [A] Remove

Kawasaki Z400 - Service manual > Fuel Pump

Kawasaki Z400 - Service manual > Fuel Pump

Fuel Pump Removal WARNING Gasoline Is extremely flammable and can be explosive under certain conditions, creating the potential for serious burns. Make sure the area is well ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light. Do not smoke. Turn the Ignition switch off. Disconnect the battery (-) terminal. To avoid fuel spills, draw it from the tank when the engine Is cold. Be prepared for fuel spillage; any spilled fuel must be completely wiped up immediately.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03