Kawasaki Z400 - Service manual > Anti-Lock Brake System (Equipped Models)

Kawasaki Z400 - Service manual > Anti-Lock Brake System (Equipped Models)

Parts Location

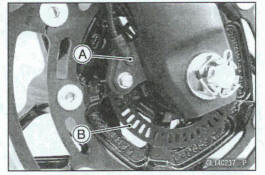

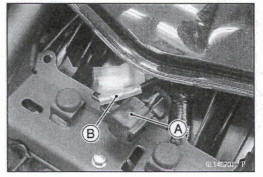

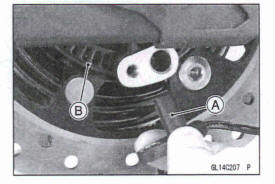

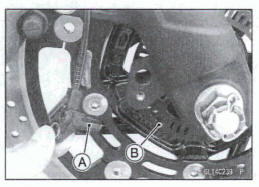

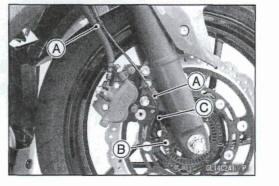

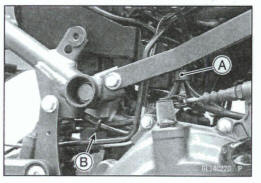

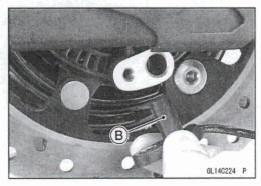

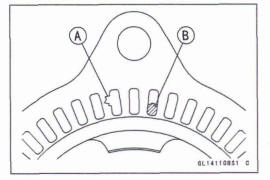

Front Wheel Rotation Sensor [A] Front Wheel Rotation Sensor Rotor [B]

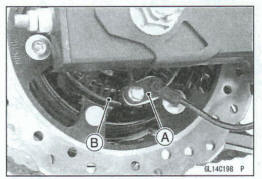

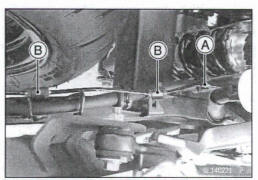

Rear Wheel Rotation Sensor [A] Rear Wheel Rotation Sensor Rotor [B]

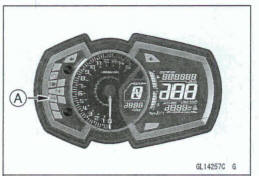

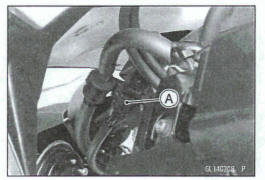

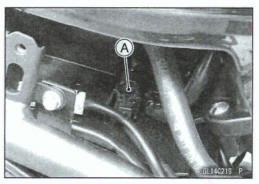

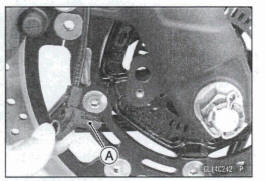

Yellow ABS Indicator Light (LED) [A]

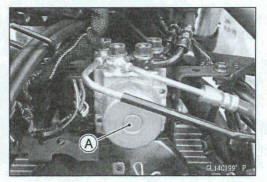

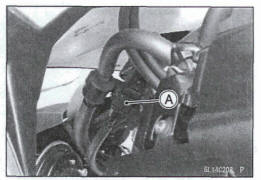

ABS Hydraulic Unit [A]

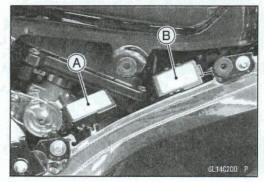

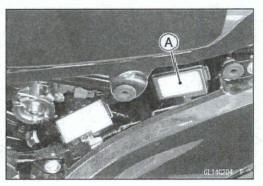

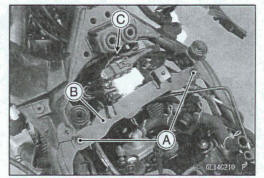

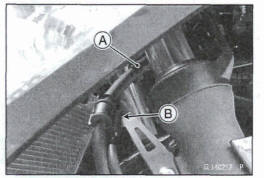

Fuse Box (1) [A] Fuse Box (2) [B]

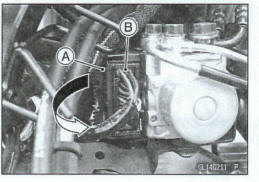

ABS Kawasaki Diagnostic System Connector [A] ABS Self-diagnosis Terminal [B]

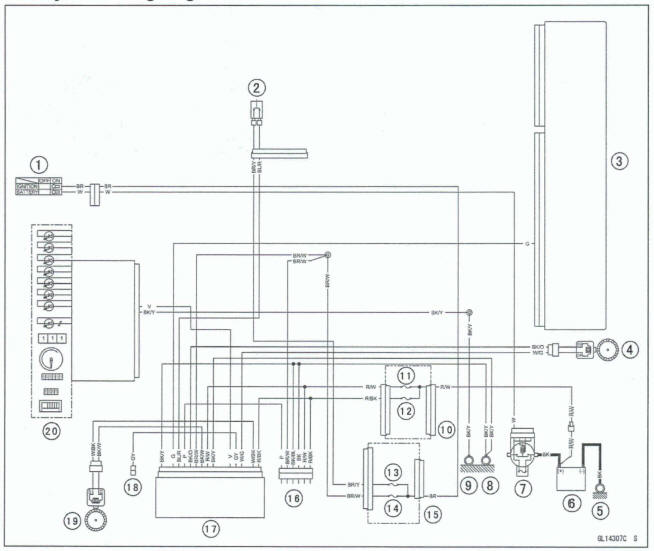

ABS System Wiring Diagram

- Ignition Switch

- Front Brake Light Switch

- ECU

- Rear Wheel Rotation Sensor

- Engine Ground

- Battery

- Main Fuse 30 A

- Frame Ground 8

- Frame Ground 4

- Fuse Box (2)

- ABS Motor Relay Fuse 30 A

- ABS Solenoid Valve Relay Fuse 20 A

- Brake/Horn Fuse 10 A

- Ignition Fuse 10 A

- Fuse Box (1)

- ABS Kawasaki Diagnostic System Connector

- ABS Hydraulic Unit

- ABS Self-diagnosis Terminal

- Front Wheel Rotation Sensor

- Meter Unit

Color Codes:

BK: Black

GY: Gray

BL: Blue

LB: Light Blue

BR: Brown

LG: Light Green

CH: Chocolate

O: Orange

DG: Dark

Green P: Pink

G: Green

PU: Purple

R: Red

V: Violet

W: White

Y: Yellow

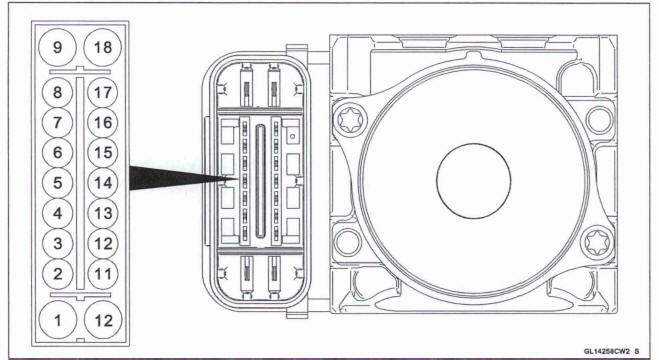

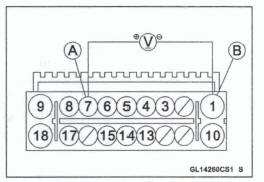

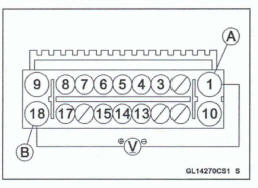

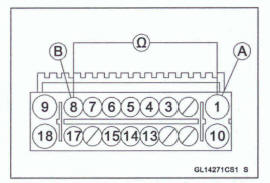

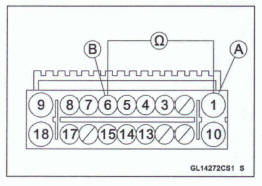

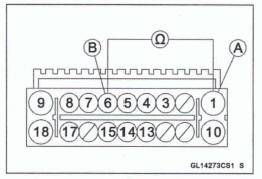

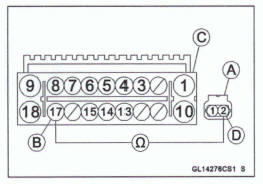

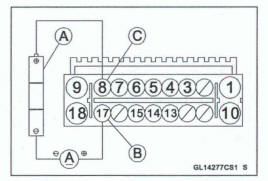

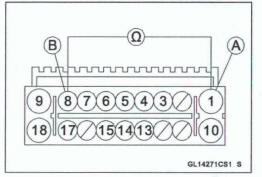

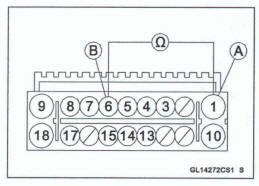

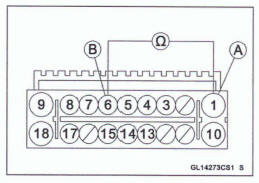

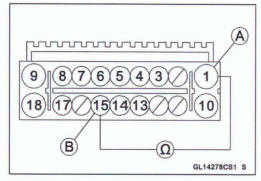

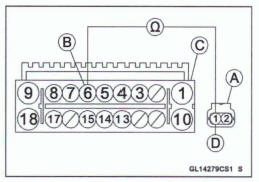

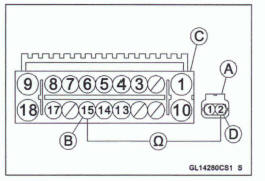

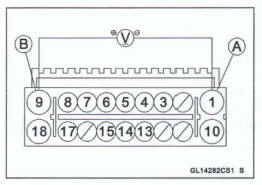

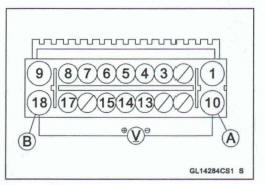

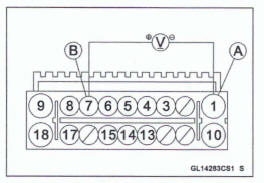

ABS Hydraulic Unit Terminal Names

- Ground: BK/Y

- Unused

- Rear Wheel Rotation Sensor Signal Output: G

- Front and Rear Brake Light Switch Signal: BUR

- ABS Kawasaki Diagnostic System Terminal: P

- Power Supply to Rear Wheel Rotation Sensor: BK/O

- Power Supply: BRAN

- Power Supply to Front Wheel Rotation Sensor: BK/W

- Power Supply to ABS Motor Relay: WW

- Ground: BK/Y

- Unused

- Unused

- Yellow ABS Indicator Light (LED): V

- ABS Self-Diagnosis Terminal: GY

- Rear Wheel Rotation Sensor Signal Input: WIG

- Unused

- Front Wheel Rotation Sensor Signal Input W/ BK

- Power Supply to ABS Solenoid Valve Relay: R/ BK

ABS Servicing Precautions

There ere a number of important precautions that should be followed servicing the ABS system.

- This ABS is designed to be used with a 12 V sealed battery as its power source. Do not use any other battery except for a 12 V sealed battery as a power source.

- Do not reverse the battery cable connections. This will damage the ABS hydraulic unit.

- To prevent damage to the ABS parts, do not disconnect the battery cables or any other electrical connections when the ignition switch is on or while the engine is running.

- Take care not to short the leads that are directly connected to the battery positive (+) terminal to the chassis ground.

- Do not turn the ignition switch on while any of the ABS electrical connectors are disconnected. The ABS hydraulic unit memorizes service codes.

- Do not spray water on the electrical parts, ABS parts, connectors, leads and wiring.

- If a transceiver is installed on the motorcycle, make sure that the operation of the ABS is not influenced by electric wave radiated from the antenna. Locate the antenna as far as possible away from the ABS hydraulic unit.

- Whenever the ABS electrical connections are to be disconnected, first turn the ignition switch off.

- The ABS parts should never be struck sharply, as with a hammer, or allowed to fall on a hard surface. Such a shock to the parts can damage them.

- The ABS parts cannot be disassembled. Even if a fault is found, do not try to disassemble and repair the ABS parts, replace it.

- The ABS has many brake lines, pipes, and leads. And the ABS cannot detect problems with the conventional braking system (brake disc wear, unevenly worn brake pad, and other mechanical faults). To prevent trouble, check the brake lines and pipes for correct routing and connection, the wiring for correct routing, and the brakes for proper braking power. Be sure to check for fluid leakage, and bleed the brake line thoroughly.

WARNING

Air In the brake lines diminish braking performance and can cause an accident resulting In injury or death. If any of the brake line fittings, including the ABS hydraulic unit joint nuts, or the bleed valve Is opened at any time, the at must be bled completely from the brake line. If the brake lever has a soft or "spongy" feeling mushy when it Is applied, there might be air In the brake lines or the brake may be defective. Do not operate the vehicle and service the brake system immediately.

NOTICE

Do not ride the motorcycle with air in the brake line, or the ABS could malfunction.

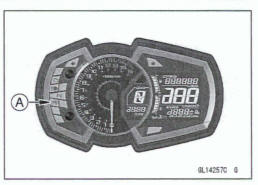

The yellow ABS indicator light (LED) [A] may light if the tire pressure is incorrect, a non-recommended tire is installed, or the wheel is deformed. If the indicator light lights, remedy the problem and dear the service code.

WARNING

Use of non-recommended Urns may cause malfunctioning of ABS and can bad to extended braking distance resulting in an accident causing serious injury or death. Always use recommended standard tires for this motorcycle.

The yellow ABS indicator light (LED) may come on if the engine is run with the motorcycle on its stand and the transmission in gear. If the indicator light comes on, just turn the ignition switch off, then dear service code 42, which indicates a 'Faulty front wheel rotation sensor.

When the ABS operates, the ABS makes noise and the rider feels the reaction force on the brake lever and brake pedal. This is a normal condition. It informs the rider that the ABS is operating normally.

Service codes detected once by the ABS hydraulic unit will be memorized in the ABS hydraulic unit. Therefore, after maintenance work is finished, be sure to erase the service codes. Do not erase the service codes during troubleshooting. Wait until all the checks and repair work are finished to prevent duplication of previous service codes and unnecessary maintenance work.

Before delivering the motorcycle to the customer, be sure to erase any service codes which might be stored in the ABS hydraulic unit. Using the self-diagnosis feature, make sure that the yellow ABS indicator light (LED) lights.

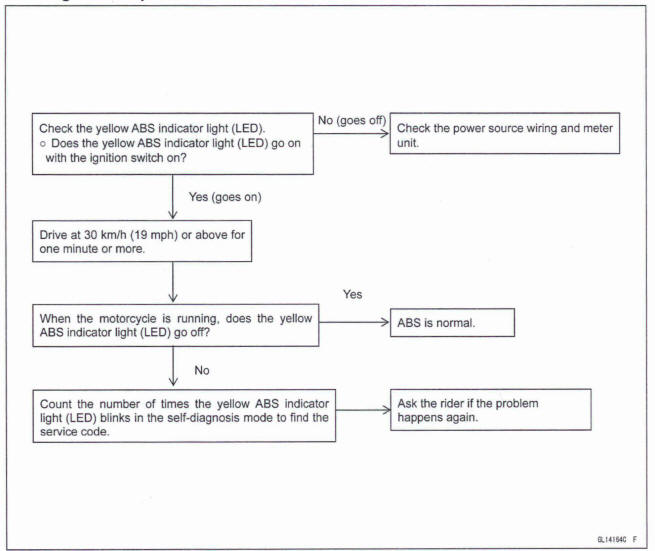

A fully charged battery is a must for conducting reliable self-diagnosis. Test run the motorcycle at a speed of more than 30 km/h (I9 mph) to see that the yellow ABS indicator light (LED) does not come on. Finally, test run the motorcycle at a speed of more than 30 km/h (1 9 mph) and brake suddenly to see that the motorcycle stops without loss of steering control and the ABS operates normally (the reaction force generated is felt in the brake lever and pedal). This completes the final inspection.

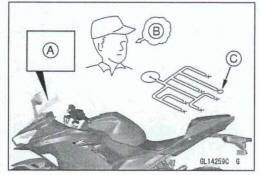

ABS Troubleshooting Outline

When an abnormality in the system occurs, the yellow ABS indicator light (LED) lights up to alert the rider. In addition, the nature of the fault is stored in the memory of the ABS hydraulic unit and when in the self-diagnosis mode, the service code [A] is indicated by the number of times the yellow ABS indicator light (LED) blinks. The service codes stored in memory are not erased until the mode has been changed to the fault erase mode after the fault has been corrected. Therefore, after correcting the problem, always erase the service codes and then run the self-diagnosis program to confirm normal signal output. When, due to a malfunction, the yellow ABS indicator light (LED) remains lit, get a thorough understanding of the background before starting the repair work. Ask the rider about the conditions [B] under which the problem occurred and try to determine the cause [C]. Do not rely solely on the ABS self-diagnosis function, use common sense; check the brakes for proper braking power, and brake fluid level, search for leaks, etc.

Even when the ABS is operating normally, the yellow ABS indicator light (LED) may light up under the conditions listed below. Turn the ignition switch off to stop the indicator light.

If the motorcycle runs without erasing the service code, the light may light up again

- After continuous riding on a rough road.

- When the engine is started with the stand raised and the transmission engaged, and the rear wheel turns.

- When accelerating so abruptly that me front wheel leaves the ground.

- When the ABS has been subjected to strong electrical interference.

- When tire pressure is abnormal. Adjust tire pressure.

- When a tire different in size from the standard size is being used. Replace with standard size.

- When the wheel is deformed. Replace the wheel.

Much of the ABS troubleshooting work consists of confirming continuity of the wiring. The ABS parts are assembled and adjusted by the manufacturer, so there is no need to disassemble or repair them. Replace the ABS hydraulic unit.

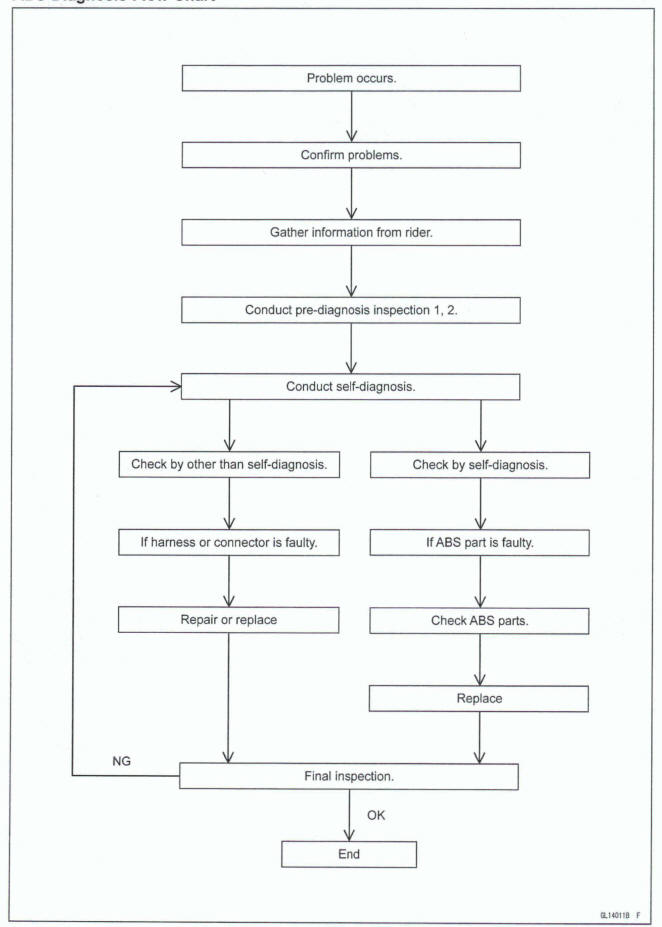

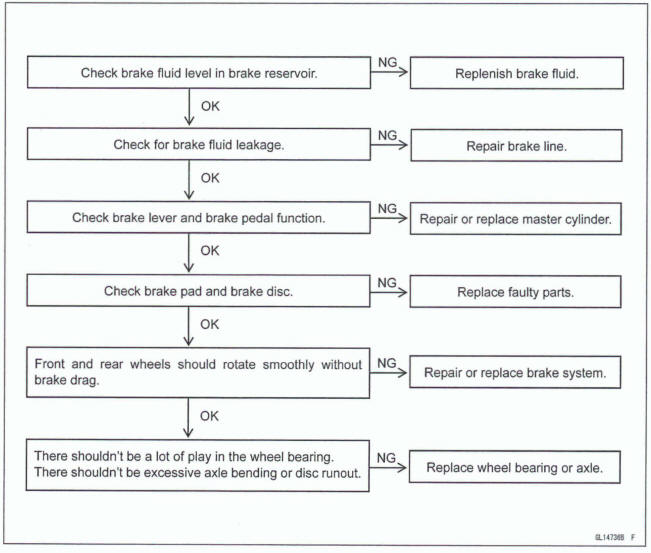

The basic troubleshooting procedures are listed below.

Carry out pre-diagnosis inspections as a preliminary inspection.

Determine the fault using the self-diagnosis function.

Check wiring and connections from the ABS hydraulic unit connector to the suspected faulty ABS part, using a digital meter

- Visually inspect the wiring for signs of burning or fraying.

*If any wiring is poor, replace the damaged wiring.

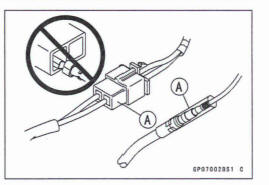

- Pull each connector [A] apart and inspect it for corrosion, dirt and damage.

*If the connector is corroded or dirty, clean it carefully. If it is damaged, replace it.

- Check the wiring for continuity.

Use the wiring diagram to find the ends of the lead which is suspected of being a problem.

Connect the digital meter between the ends of the leads.

*If the digital meter does not read about 0

, the lead is

defective. Replace the main harness if necessary.

, the lead is

defective. Replace the main harness if necessary.

- Narrow down suspicious parts and dose in on the faulty ABS part by repeating the continuity tests.

*If no abnormality is found in the wiring or connectors, the ABS parts are the next likely suspects. Check each part one by one.

*If an abnormality is found, replace the affected ABS part.

ABS Diagnosis Flow Chart

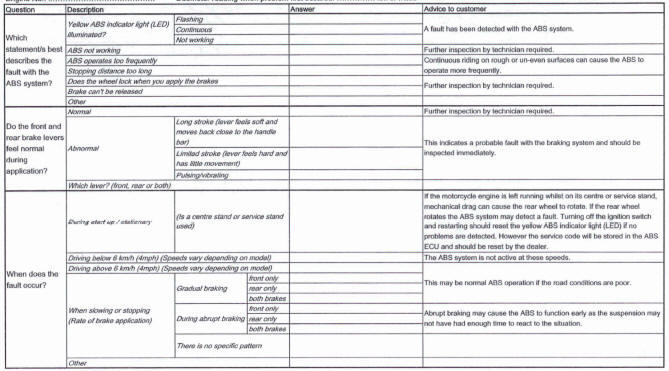

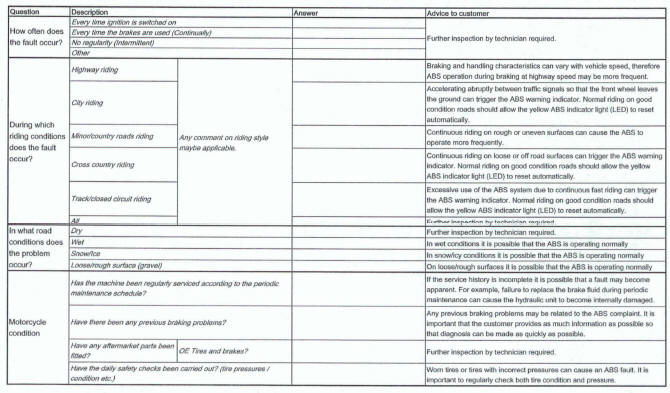

Inquiries to Rider

- Each rider reacts to problems in different ways, so it is important to confirm what kind of problem the rider is experiencing.

- Try to find out exactly what problem occurs under exactly what conditions by asking the rider, knowing this information may help you reproduce the problem in the workshop.

- The diagnosis sheet will help prevent you from overlooking any key information, so always use it.

Sample Diagnosis Sheet 1

Rider Name:...

Date of registration :...

Vin No.:...

Engine No.:...

Registration No.:...

Model:...

Odometer reading:...km or miles

Odometer reading when problem first occured:.... km or miles

Dealer Findings

Sample Diagnosis Sheet 2

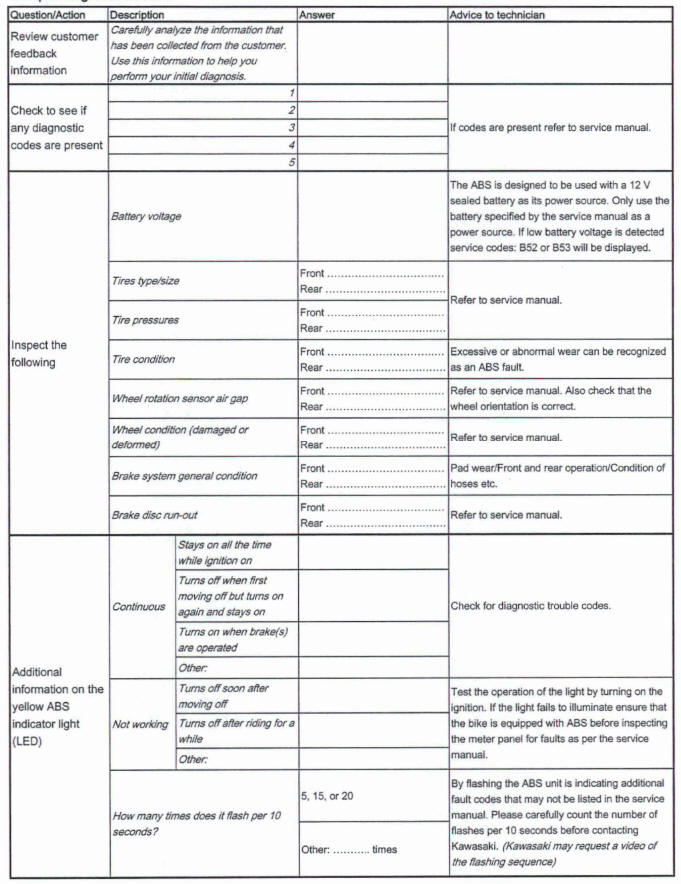

Pre-Diagnosis Inspection 1

Pre-Diagnosis Inspection 2

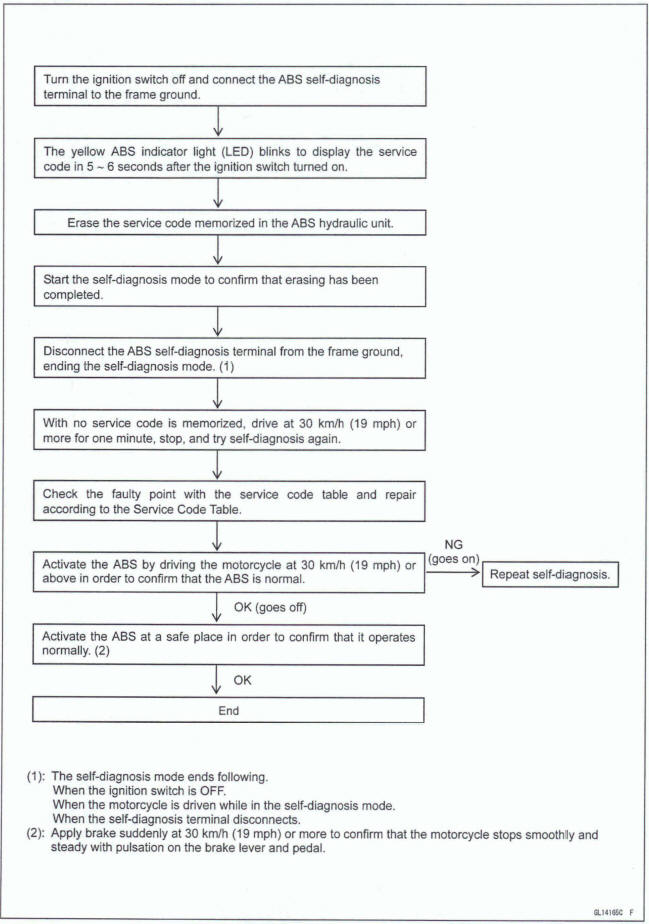

Self-diagnosis Outline

When the yellow ABS indicator light (LED) has blinked or come on, the ABS hydraulic unit memorizes and stores the service code for the service person to troubleshoot easily. The service code memory is powered directly by the battery and cannot be canceled by the ignition switch.

The ABS hydraulic unit can memorize up to all service codes. Further service codes are memorized after erasing the preceding all service codes. If there is no fault, the yellow ABS indicator light (LED) lights, indicating that "The ABS is normal."

Self-diagnosis Procedures

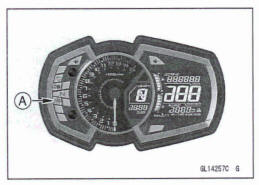

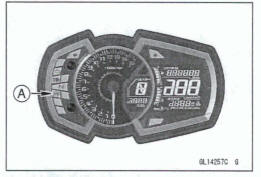

- Before performing the self-diagnosis procedures, make sure that the yellow ABS Indicator light (LED) [A] stays on to indicate any electrical problem occurring in the ABS.

NOTE

- Use a fully charged battery for performing self-diagnosis procedure properly. A insufficient battery may cause improperly result.

- The self-diagnosis procedures should be done with the motorcycle is stopped

- The ABS hydraulic unit can be store the service codes including previous ones.

- To read out the current service code, erase the stored service codes once prior reading the =Mice code (see Service Code Clearing Procedures).

- Test ride the motorcycle with 30 km/h (1 9 mph) or more in a safety area to store the service code, which correspond to the current problems.

- Remove the front seat (see Front Seat Removal in the Frame chapter).

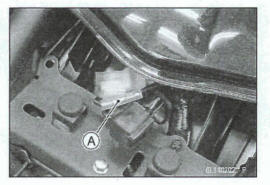

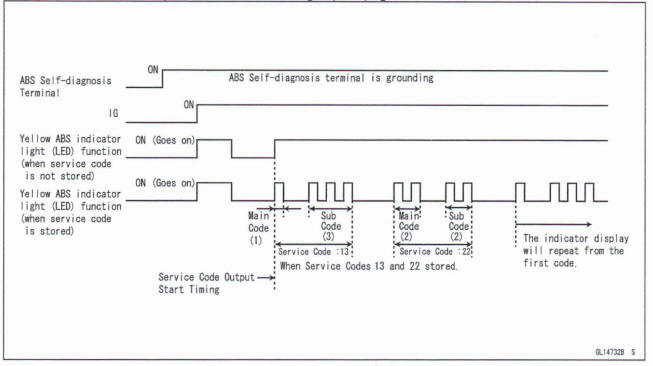

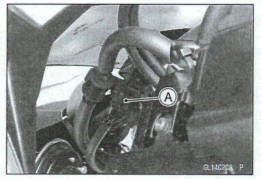

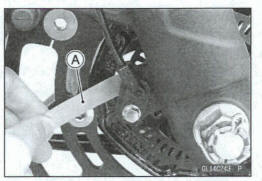

- Ground the self-diagnosis terminal [A] (Gray) to a frame ground, using a suitable auxiliary lead. Keep the auxiliary lead ground during self-diagnosis procedure.

- Turn the ignition switch to on and read the service code (see How to Read Service Code).

- To exit the self-diagnosis mode, remove the auxiliary lead from the self-diagnosis terminal.

NOTE

The grounding auxiliary lead must be removed after the self-diagnosis procedure.

Service Code Clearing Procedures

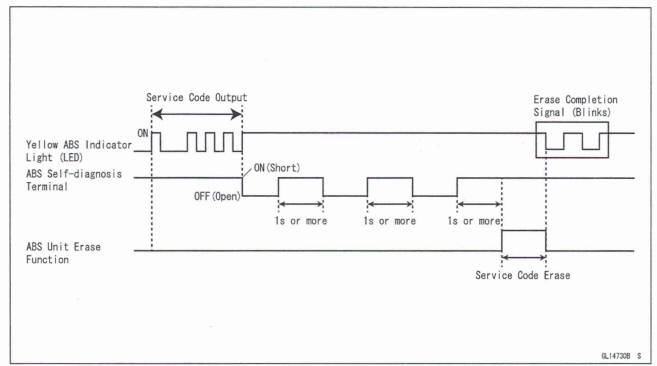

Start the service code erase mode with the following procedure

- The erase mode starts when the ABS self-diagnosis terminal is disconnected from the frame ground after starting the self-diagnosis mode.

- The service code can be erased by grounding (time for at least one second) and ungrounding the ABS self-diagnosis terminal three times or more within about 12.5 seconds after starting the erase mode and grounding it.

- The yellow ABS indicator light (LED) remains lit during the erase mode.

- After erasing, the yellow ABS indicator light (LED) blinks two times and lights.

- Once erasing is finished, enter the self-diagnosis mode again to confirm that the service codes have been erased. W the ABS has been reset and all codes have been erased, the yellow ABS indicator light (LED) lights.

Self-diagnosis Flow Chart

How to Read Service Codes

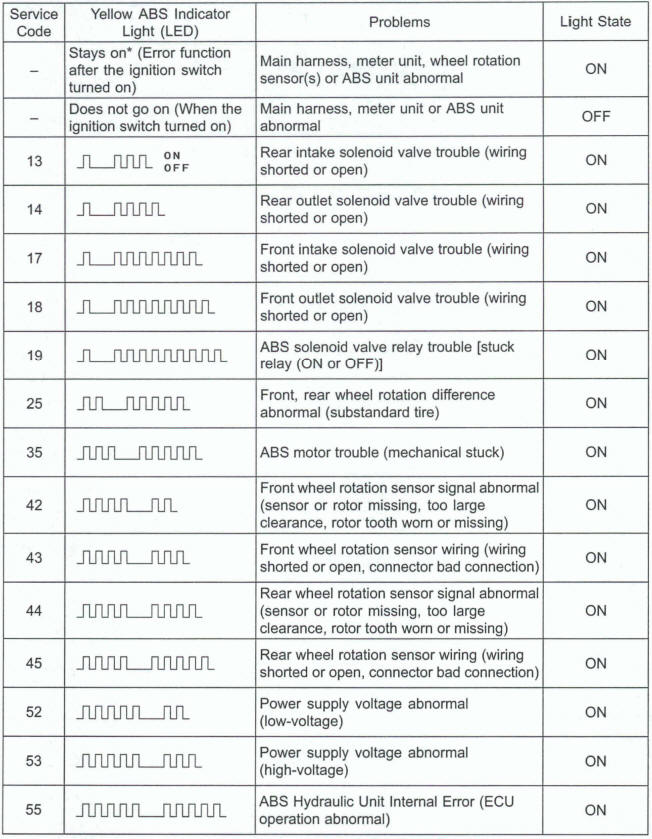

- Service codes are shown by a series of long and short blinks of the yellow ABS indicator light (LED) as shown below.

- Read 10th digit and unit digit as the yellow ABS indicator light (LED) blinks.

- When there are a number of faults, a maximum of all service codes can be stored.

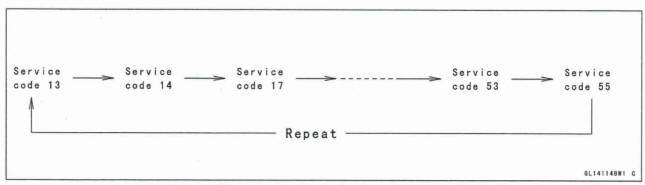

- For the display pattern, the display will begin starting from the small number code entered, then the display is repeated from the smallest number code once again.

If there is no fault, the yellow ABS indicator light (LED) lights as shown.

How to Erase Service Codes

- Even if the ignition switch is turned off, the battery or the ABS hydraulic unit are disconnected, all service codes remain in the ABS hydraulic unit.

- Refer to the Service Code Clearing Procedure for the service code erasure.

Service Code Table

*: In spite of the service code is not stored, the yellow ABS Indicator Light (LED) does not go off when the 2 seconds later from the ignition switch turned on.

Yellow ABS Indicator Light (LED) Inspection

In this model, the yellow ABS indicator light (LED) [A] goes on or blinks by the control of the ABS hydraulic unit.

Yellow ABS Indicator Light (LED) Stays On (Error function after the Ignition switch turned on - No Service Code)

- Perform the Pre-Diagnosis Inspection 1.

- Check the system connectors for loose or poorly contact.

Step I

- Check the ignition fuse 10 A in the fuse box (1) [A] for blown.

*If the fuse Is blown, replace the fuse.

*If the fuse is not Mown, go to next step.

Step 2

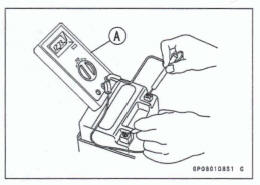

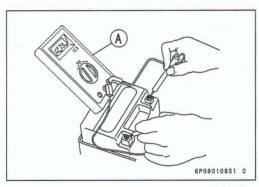

- Measure the battery terminal voltage using a voltmeter [A].

- The battery voltage should be within 10 - 16 V.

*If the voltage without specifications, recharge or replace the battery.

*If the voltage within specifications, go to next step.

Step 3

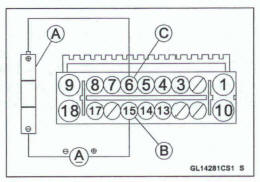

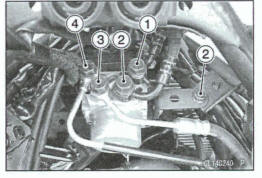

- Disconnect the ABS hydraulic unit connector.

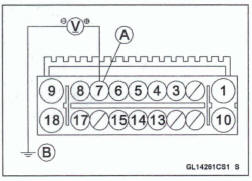

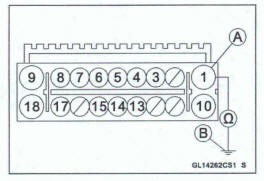

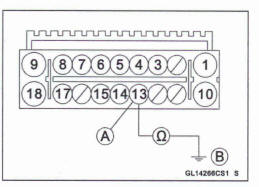

- Check the voltage between the terminal 7 (BR/W) (+) [A] and terminal 1 (BK/Y) (-) [B] of the ABS hydraulic unit connector.

The battery voltage (10 - 16 V) should be appeared while the ignition switch turned on.

*If the battery voltage appeared, go to step 4.

*If the battery voltage does not appear, go to next step.

Step 3-1

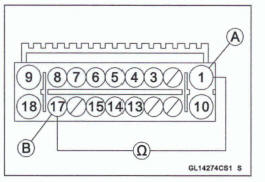

- Check the voltage between the terminal 7 (BR/W) (+) [A] of the ABS hydraulic unit connector and a frame ground (-) [B].

The battery voltage (10 - 18 V) should be appeared while the ignition switch turned on.

*If the battery voltage does not appear, repair or replace the main harness.

*If the battery voltage appeared, go to next step.

Step 3-2

- Check for continuity between the terminal 1 (BW) [A] of the ABS hydraulic unit connector and a frame ground [B].

*If there is no continuity, repair or replace the main harness.

*If there is continuity, replace the ABS hydraulic unit.

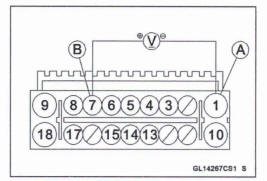

Step 4

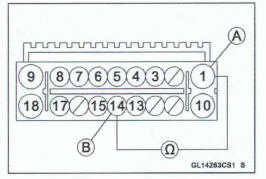

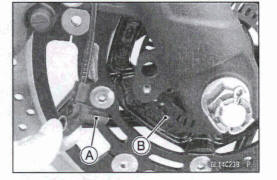

- With the self-diagnosis terminal connected to the ground, check for continuity between the terminal1 (BW) [A] and terminal 14 (GY) [B] of the ABS hydraulic unit connector.

*If there is no continuity, repair or replace the main harness.

*If there is continuity, go to next step.

Step 5

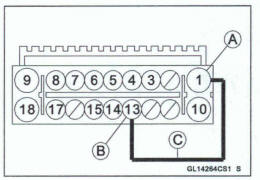

- Jump the terminal 1 (BK/Y) [A] and terminal 13 (V) [B] at the ABS hydraulic unit connector using a jumper read [C].

- Check the yellow ABS indicator light (LED) with the ignition switch turned on.

*If the indicator goes off, replace the ABS hydraulic unit.

*If the indicator goes on, go to next step.

Step 6

- Disconnect the connector from the meter unit (see Meter Unit Removal in the Electrical System chapter).

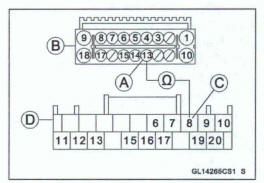

- Check for continuity between the terminal 13 (V) [A] of the ABS hydraulic unit connector [B] and terminal 8 (V) [C] of the meter connector [D].

*If there is no continuity, repair or replace the main harness.

*If there is continuity, replace the meter unit with a new one.

Yellow ABS Indicator Light (LED) does not go on (When the Ignition Switch turned on)

- Perform the Pre-Diagnosis Inspection 1.

- Check the system connectors for loose or poorly contact.

step 1

- Check the meter fuse 10 A in the fuse box (1) for blown.

*If the fuse is blown, replace the fuse.

*If the fuse is not blown, go to next step.

Step 2

- Disconnect the ABS hydraulic unit connector and check the yellow ABS indicator light (LED) for function.

The yellow ABS indicator light (LED) should goes on when the ignition switch turned on.

*If the indicator does not goes on, go to next step.

*If the indicator goes on, go to step 3.

Step 2-1

Disconnect the connector from the meter unit (see Meter Unit Removal in the Electrical System chapter).

Check for continuity between the terninall3 (V) [A] of the ABS hydraulic unit connector and a frame ground [B].

*If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the meter unit with a new one.

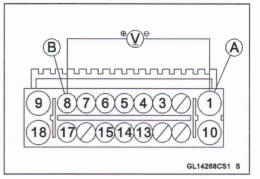

Step 3

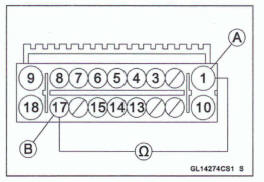

- Check the voltage between the terminal 1 (BK/Y) (-) [A] and terminal 7 (BRAN) (+) [B] of the ABS hydraulic unit connector

- The battery voltage (10 - 16 V) should not appear while the ignition switch turned off

*If the battery voltage appeared, repair or replace the main harness.

*If the battery voltage does not appear, go to next step.

Step 4

- Check the voltage between the terminal 1 (BW) (-) [A] and terminal 8 (BW) (+) [B] of the ABS hydraulic unit connector.

- The battery voltage (10 - 16 V) should not appear while the ignition switch turned off.

*If the battery voltage appeared, repair or replace the main harness.

*If the battery voltage does not appear, go to next step.

Step 5

- Check the voltage between the terminal 1 (BK/Y) (-) [A] and terminal 6 (BK/O) (+) [B] of the ABS hydraulic unit connector.

- The battery voltage (10 - 16 V) should not appear while the ignition switch turned off.

*If the battery voltage appeared, repair or replace the main harness.

*If the battery voltage does not appear, replace the ABS hydraulic unit.

ABS Unit Solenoid Valve Inspection (Service Code 13, 14, 17, 18)

These codes indicate there is a problem in the solenoid valves, which integrated into the ABS Hydraulic Unit.

Therefore the solenoid valves cannot be checked directly.

- Check the system connectors for loose or poorly contact.

- In order to confirm a existing problem in the system, erase the service code and then perform the pre-diagnosis inspection 1 and 2.

*If same service code Is indicated again, faulty solenoid valve in the ABS hydraulic unit. Replace the ABS hydraulic unit.

*If the service code does not indicate, ABS system is normal (service code is not stored; temporary failure).

ABS Solenoid Valve Relay Inspection (Service Code 19)

- Perform the Pre-Diagnosis Inspection 1 and 2.

- Check the system connectors for loose or poorly contact,

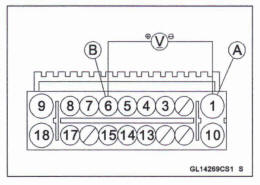

Step 1

- Check the ABS solenoid valve relay fuse 20 A in the fuse box (2) [A] for blown.

*If the ABS solenoid valve relay fuse is blown, replace the fuse.

*If the fuse is not blown, go to next step.

Step 2

- Disconnect the ABS hydraulic unit connector.

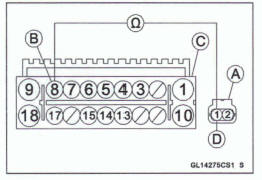

- Check the voltage between the terminal 1 (BK/Y) (-) [A] and terminal 18 (R/BK) (+) [B] of the ABS hydraulic unit connector.

The battery voltage (10 - 16 V) should appear while the ignition switch turned on.

*If the battery voltage does not appear, repair or replace the main harness.

If the battery voltage appeared, replace the ABS hydraulic unit.

Front, Rear Wheel Rotation Difference Abnormal Inspection (Service Code 25)

- Perform the Pre-Diagnosis Inspection 1 and 2.

Step 1

- Check the front and rear tire/wheel conditions for tire pressure, tire size/types, abnormal wear and deformations (see Wheels/Tires in the Periodic Maintenance chapter).

*If the tire and/or wheel are in bad condition, correct them to the normal condition.

*If there is no problem, go to next step.

Step 2

- Visually inspect the sensor rotor [A] for missing teeth or clogging with foreign matter (see Wheel Rotation Sensor Rotor Inspection).

*Clean or correct the parts if necessary.

*If the all parts correct, go to next step.

Step 3

- Measure the front and rear wheel rotation sensor air gaps (see Wheel Rotation Sensor Air Gap Inspection).

*If the air gap is not within the specification, recheck the hub bearing, sensor, sensor rotor and sensor installation condition.

*If the air gap is within the specification, replace the ABS hydraulic unit.

ABS Motor Inspection (Service Code 35)

- Perform the Pre-Diagnosis Inspection 1 and 2.

- Check the system connectors for loose or poorly contact.

- In order to confirm a existing problem in the system, erase the service code and then recheck the yellow ABS indicator light (LED).

*If same service code is indicated again, faulty ABS Motor in the ABS hydraulic unit. Replace the ABS hydraulic unit.

*If the service code does not indicate, ABS system is normal (service code is not stored; temporary failure).

Wheel Rotation Sensor Signal Abnormal Inspection (Front: Service Code 42) (Rear: Service Code 44)

Perform the Pre-Diagnosis Inspection 1 and 2.

Check the system connectors for loose or poorly contact.

Step I

- Measure the front or rear wheel rotation sensor air gap (see Wheel Rotation Sensor Air Gap Inspection).

*If the air gap Is not within the specification, recheck the hub bearing, sensor, sensor rotor and sensor installation condition.

*If the air gap is within the specification, go to next step.

Step 2

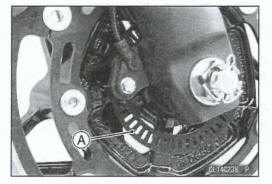

- Check that there is iron or other magnetic deposits between the front or rear wheel rotation sensor [A] and sensor rotor, and the sensor rotor slots [B] for obstructions.

- Check the installation condition of the sensor for looseness.

- Check the sensor tip and sensor rotor slots for deformation or damage (e-g. chipped sensor rotor teeth).

*If the sensor and sensor rotor in bad condition, dean or replace the faulty parts.

*If all items are correct, go to next step.

Step 3

- Check the front and rear tire/wheel conditions for tire pres- sure, tire size/types, abnormal wear and deformations (see Wheels/Tires in the Periodic Maintenance chapter).

*If the tire and/or wheel are in bad condition, correct them if necessary and recheck.

*If all items are good condition, replace the ABS unit.

Front Wheel Rotation Sensor Wiring Inspection (Service Code 13)

This code is indicates there is a trouble in the front wheel rotation sensor.

Perform the Pre-Diagnosis Inspection 1 and 2.

Check the system connectors for loose or poorly contact.

Step 1

Disconnect the ABS hydraulic unit connector.

Check for continuity between the terminal 1 (BK/Y) [A] and terminal 8 (BW) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 2.

Step 1-1

Disconnect the front wheel rotation sensor connector [A].

Recheck the continuity between the terminal 1 (BW) and terminal 8 (BK/W) of the ABS hydraulic unit connector.

*If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the front wheel rotation , sensor.

Step 2

- Check for continuity between the terminal 1 (BK/Y) [A] and terminal 8 (BK/O) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 3.

Step 2-1

- Disconnect the rear wheel rotation sensor connector.

- Recheck the continuity between the terminal 1 (BW) [A] and terminal 6 (BK/O) [B] of the ABS hydraulic unit connector.

*If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the rear wheel rotation sensor.

Step 3

- Connect the front wheel rotation sensor connector.

- Check for continuity between the terminal1 (BW) [A] and terminal 17 (W/BK) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 4.

Step 3-1

- Disconnect the front wheel rotation sensor connector.

- Recheck the continuity between the terminal 1 (BW) [A] and terminal 17 (W/BK) [B] of the ABS hydraulic unit connector

* If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the front wheel rotation sensor.

Step 4

- Disconnect the front wheel rotation sensor connector [A].

- Check for continuity between the terminal 8 (BK/W) [B] of the ABS hydraulic unit connector [C] and terminal 1 (BW) [Dl of the front wheel rotation sensor connector (main harness side).

*If there is no continuity, repair or replace the main harness.

*If there is continuity, go to next step.

Step 5

- With disconnecting the front wheel rotation sensor connector [A], check for continuity between the terminal 17 (W/BK) [B] of the ABS hydraulic unit connector [C] and the 2 (W/BK) terminal [Dl of the front wheel rotation sensor connector (main harness side).

*If there is no continuity, repair or replace the main harness.

*If there is continuity, go to next step.

Step 6

Connect the front wheel rotation sensor connector.

Connect the 4.5 - 5.0 V DC power (e-g. three AA dry battery in series [A]) between the terminal 17 (W/BK) (-) [B] and terminal 8 (BW) (+) [C] of the ABS hydraulic unit connector to measure DC amperage.

- Be careful not to reverse connection of the DC power polarity.

- The measured DC amperage should be within 3 - 17mA.

*If measurement is abnormal, replace the front wheel rotation sensor.

*If measurement is normal, replace the ABS hydraulic unit.

Rear Wheel Rotation Sensor Wiring Inspection (Service code 45)

This code is indicates there is a trouble in the rear wheel rotation sensor. However the front and rear wheel rotation sensor inspection should be performed if this code is indicated

- Perform the Pre-Diagnosis Inspection 1 and 2.

- Check the system connectors for loose or poorly contact.

Step 1

- Disconnect the ABS hydraulic unit connector.

- Check for continuity between the terminal 1 (BW) [A] and terminal 8 (W/BK) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 2.

Step 1

- Disconnect the ABS hydraulic unit connector.

- Check for continuity between the terminal 1 (BW) [A] and terminal 8 (W/BK) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 2.

Step 1-1

Disconnect the front wheel rotation sensor connector [A].

Recheck the continuity between the terminal 9 (BK/Y) and terminal 8 (W/BK) of the ABS hydraulic unit connector

*If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the front wheel rotation sensor.

Step 2

- Check for continuity between the terminal 1 (BK/Y) [A] and terminal 6 (BK/O) [B] of the ABS hydraulic unit connector.

*If there is continuity, go to next step.

*If there is no continuity, go to step 3.

Step 2-1

- Disconnect the rear wheel potation sensor connector.

- Recheck the continuity between the terminal 1 (BW) [A] and terminal 6 (BK/O) [B] of the ABS hydraulic unit connector

*If there is continuity, repair or replace the main harness.

*If there is no continuity, replace the rear wheel rotation sensor.

Step 3

- Connect the rear wheel rotation sensor connector.

- Check for continuity between the terminal 1 (BK/Y) [A] and terminal 15 (WIG) [B] of the ABS hydraulic unit connector

*If there is continuity, go to next step.

*If there is no continuity, go b step 4.

Step 3-1

- Disconnect the rear wheel rotation sensor connector [A].

- Recheck the continuity between the terminal 1 (BK/Y) and terminal 15 (WIG) of the ABS hydraulic unit connector.

*If there is continuity, repair or replace a the main harness.

*If there is no continuity, replace the rear wheel rotation sensor.

Step 4

- Disconnect the rear wheel rotation sensor connector [A].

- Check for continuity between the terminal 6 (BK/O) [B] of the ABS hydraulic unit connector [C] and terminal 1 (BK/O) [D] of the rear wheel rotation sensor connector (main harness side).

*If there is no continuity, repair or replace the main harness.

*If there is continuity, go to next step

Step 5

- With disconnecting the mar wheel rotation sensor connector [A], check for continuity between the terminal 15 (WIG) [B] of the ABS hydraulic unit connector [C] and terminal 2 (WIG) [Dl of the rear wheel rotation sensor connector (main harness side).

*If there is no continuity, repair or replace the main harness.

*If there is continuity, go to next step.

Step 6

Connect the rear wheel rotation sensor connector.

Connect the 4.5 - 5.0 V DC power (e.g. three AA dry battery in series [A]) between the terminal 15 (WIG) (-) [B] and terminal 6 (BK/O) (+) [C] of the ABS hydraulic unit connector to measure DC amperage.

- Be careful not to reverse connection of the DC power polarity.

- The measured DC amperage should be within 3 ~17 mA.

*If measurement is abnormal, replace the rear wheel rotation sensor.

*If measurement is normal, replace the ABS hydraulic unit.

Power Supply Voltage Abnormal inspection (Service Code 52: Low Voltage) (Service Code 53: High Voltage)

Step 1

- Measure the battery terminal voltage using a voltmeter [A].

The battery voltage should be within 10 - 16 V.

*If the voltage is not within the specifications, recharge or replace the battery.

*If the voltage within the specifications, go to next step.

Step 2

- Check the ABS motor relay fuse 30 A and ABS solenoid valve relay fuse 20 A in the fuse box (2) [A] for blown.

*If the fuse(s) is blown, replace the fuse(s).

*If the fuse(s) is not blown, go to next step.

Step 3

- Disconnect the ABS hydraulic unit connector.

- Check the voltage between the terminal 1 (BK/Y) (-) [A] and terminal 9 (R/W) (+) [B] of the ABS hydraulic unit connector.

The battery voltage (10 - 16 V) should appear while the ignition switch turned on.

*If the battery voltage does not appear, repair or replace the main harness.

*If the battery voltage appeared, go to next step.

Step 4

Disconnect the ABS hydraulic unit connector.

Check the voltage between the terminal 10 (BK/Y) (-) [A] and terminal 18 (R/BK) (+) [B] of the ABS hydraulic unit connector.

The battery voltage (10 - 16 V) should appear while the ignition switch turned on.

*If the battery voltage does not appear, repair or replace the main harness.

*If the battery voltage appeared, go to next step.

Step5

Check the voltage between the terminal 1 (BK/Y) (-) [A] and terminal 7 (BR/W) (+) [B] of the ABS hydraulic unit connector

The battery voltage (10 - 16 V) should appear while the ignition switch turned on.

*If the battery voltage not appeared, repair or replace the main harness.

*If the battery voltage does appear, replace the ABS hydraulic unit.

ABS Hydraulic Unit Internal Error Inspection (Service Code 55)

This service code indicates there is an internal error for the ECU integrated with the ABS hydraulic unit regarding the wheel speed detection.

- Perform the Pre-Diagnosis Inspection 1 and 2.

- Check the system connectors for loose or poorly contact.

Step I

- Measure the front end rear wheel rotation sensor air gaps (see Wheel Rotation Sensor Air Gap Inspection).

*If the air gap is not within the specification, correct the air gap accordingly.

*If the air gap is within the specification, go to next step.

Step 2

- Check that there is iron or other magnetic deposits between the both wheel rotation sensor [A] and sensor rotor, and the sensor rotor slots [B] for obstructions.

- Check the installation condition of the sensor for looseness.

- Check the sensor tip and sensor rotor slots for deformation or damage (e.g. chipped sensor rotor teeth).

*If the sensor and sensor rotor in bad condition, dean or replace the faulty parts.

*If all items are correct, go to next step.

Step 3

- Check the front and mar tireJwhee1 conditions for tire pressure, tire size/types, abnormal wear and deformations (see Wheels/Tires the Periodic Maintenance chapter).

*If the tire and/or wheel are in bad condition, correct them to the normal condition.

*If there is no problem, replace the ABS hydraulic unit.

ABS Hydraulic Unit Removal

NOTICE

The ABS hydraulic unit [A] has been adjusted and set with precision at the factory. Therefore, It should be handled carefully, never struck sharply, as with a hammer, or allowed to fall on a hard surface.

Be careful not to get water or mud on the ABS hydraulic unit.

NOTICE

Brake fluid quickly damage painted plastic surfaces; any spilled fluid should be completely washed away immediately.

- Drain the brake fluid from the front and rear brake lines.

Drain the brake fluid through the bleed valve by pumping the brake lever and pedal.

Be sure to place a cloth under the ABS hydraulic unit.

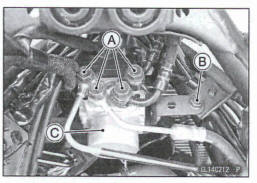

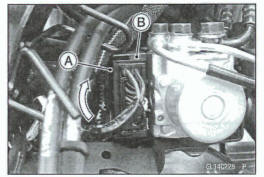

- Remove: Air Cleaner Housing (see Air Cleaner Housing Removal in the Fuel System (DFI) chapter) Air Cleaner Housing Bracket Bolts [A] Air Cleaner Housing Bracket [B]

- Open the clamp [C].

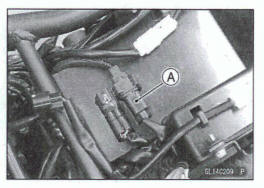

Pull the lever [A] to disconnect the ABS hydraulic unit Connector [B]

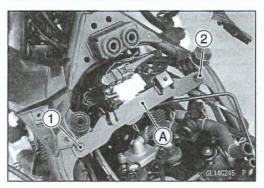

- Remove: Brake Hose Banjo Bolts (ABS Hydraulic Unit) [A] ABS Hydraulic Unit Bracket Bolts [B] ABS Hydraulic Unit [C]

NOTE

Be careful not to bend the brake pipe while removing the ABS hydraulic unit.

- Plug the port [A] on the ABS hydraulic unit to prevent entering a foreign matter into the unit.

- Wrap the brake pipe openings with a vinyl bag to prevent brake fluid leakage and entering a foreign matter into the hydraulic system.

NOTICE

- Do not allow entering a foreign matter into the hydraulic system while disconnecting the hydraulic lines

- Brake fluid quickly ruins painted plastic surfaces; any spilled fluid should be completely washed away immediately.

- Remove: Bolts [A] and Collars Bracket [B]

Notice

The ABS hydraulic unit has been adjusted and set with precision at the factory. Do not try to disassemble and repair the ABS hydraulic unit.

ABS Hydraulic Unit Installation

NOTICE

Brake fluid quickly damage painted plastic surfaces; any spilled fluid should be completely washed away immediately.

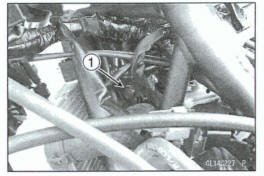

Install the ABS hydraulic unit together with the bracket, and tighten the bolts following the specified tightening sequence [1 - 2].

Replace the washers that are on each side of pipe fitting with new ones.

Install the brake hoses (see Cable, Wire, and Hose Routing section in the Appendix chapter).

Tighten the brake hose banjo bolts (ABS hydraulic unit) following the specified tightening sequence [1 - 4].

Torque - Brake Hose Banjo Bolts (ABS Hydraulic Unit): 33 N-m (3.4 kgf-m, 24 ft-lb)

- Push the lever [A] to connect the ABS hydraulic unit connector [B]

- Bleed the brake line (see Brake Line Bleeding).

- Check the brake for good braking power, no brake drag, and no fluid leakage.

- Install the air cleaner housing bracket [A].

- Tighten the air cleaner housing bracket bolts following the specified tightening sequence [1 - 2].

Toque -Air Cleaner Housing Bracket Bolts: 25 N*m (2.5 kgf*m, 18 R-lb)

- Install the removed parts (see appropriate chapters).

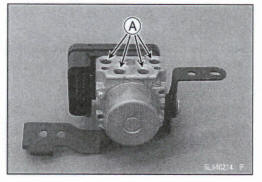

ABS Hydraulic Unit Inspection

- Remove the ABS hydraulic unit (see ABS Hydraulic Unit Removal).

- Visually inspect the ABS hydraulic unit.

*Replace the ABS hydraulic unit if any of them are cracked, or otherwise damaged.

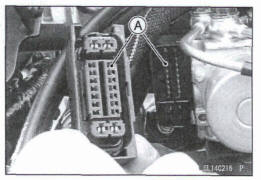

- Visually inspect the connector terminals [A].

*Replace the ABS hydraulic unit or main harness if either of the terminals are cracked, bent, or otherwise damaged, *If the ABS hydraulic unit connector is clogged with mud or dust, blow it off with compressed air.

Front Wheel Rotation Sensor Removal

NOTICE

The wheel rotation senor should be handled carefully, never struck sharply, as with a hammer, or allowed to fall on s hard surface since the wheel rotation sensor Is precision made. Be careful not to get water or mud on the wheel rotation sensor.

Do not try to disassemble or repair the wheel rotation sensor.

- Disconnect the front wheel rotation sensor connector [A] and free the connector from the bracket

- Clear the sensor lead from the damp [A] and bracket [B].

- Remove: Clamps [A] Front Wheel Rotation Sensor Bolt [B] Front Wheel Rotation Sensor [C]

Front Wheel Rotation Sensor Installation

- Installation is the reverse of removal.

Run the lead correctly (see Cable, Wire, and Hose Routing section in the Appendix chapter).

Tighten:

Torque -Front Wheel Rotation Sensor Bolt: 6.9 N-m (0.70 kgf*m, 61 in-lb)

Rear Wheel Rotation Sensor Removal

NOTICE

The wheel rotation sensor should be handled carefully, never struck sharply, as with a hammer, or allowed to fall on a hard surface since the wheel rotation sensor is precision made. Be careful not to get water or mud on the wheel rotation sensor.

Do not try to disassemble or repair the wheel rotation sensor.

- Remove: Right Middle Fairing (see Middle Fairing Removal in the Frame chapter) Frame Cover (see Frame Cover Removal in the Frame chapter) Mud Guard (see Mud Guard Removal in the Frame chapter)

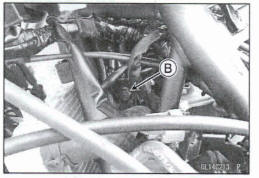

- Disconnect the rear wheel rotation sensor connector [A] and free the connector from the battery case cover.

- Open the damp [A].

- Clear the sensor lead from the bracket [B].

- Remove the damp [A].

- Clear the sensor lead from the brackets [B].

- Remove: Rear Wheel Rotation Sensor Bolt [C] Rear Wheel Rotation Sensor [D]

Rear Wheel Rotation Sensor Installation

Installation is the reverse of removal.

- Run the lead correctly (see Cable, Wire, and Hose Routing section in the Appendix chapter).

- Tighten:

Torque -Rear Wheel Rotation Sensor Bolt: 6.9 N-m (0.70 kgf*m, 61 in*lb)

Wheel Rotation Sensor Inspection

- Remove the front wheel rotation sensor [A] from the front fork.

- Remove the rear wheel rotation sensor [B] from the caliper bracket.

- Visually inspect the wheel rotation sensors.

*Replace the wheel rotation sensor if it is cracked, bent, or otherwise damaged.

*If electrical failure is suspected on the sensors, perform the electrical check (see Service Code 43 Step 6 for front sensor or Service Code 45 Step 6 for rear sensor).

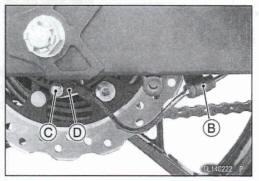

Wheel Rotation Sensor Air Gap Inspection

- Raise the front/rear wheel off the ground (see Front/Rear Wheel Removal in the Wheels/Tires chapter).

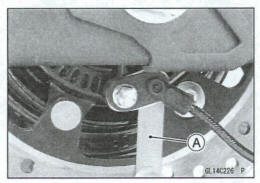

- Measure the air gap between the sensor and sensor rotor

at several points.

Thickness Gauge [A]

Air Gap

Standard:

Front 0.6 - 1 .5 mm (0.02 - 0.06 in.)

Rear 0.8 - 1.5 mm (0.03 - 0.06 in.)

NOTE

The sensor air gap cannot be adjusted.

*If the air gap is not within the specification, inspect the hub bearing (see Hub Bearing Inspection in the Wheels/Tires chapter), sensor, sensor rotor and sensor installation condition (see Wheel Rotation Sensor Inspection).

Front Wheel Rotation Sensor Rotor Removal

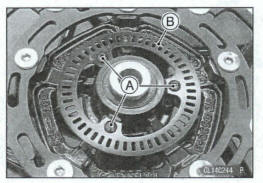

- Remove: Front Wheel (see Front Wheel Removal in the Wheels/ Tires chapter) Front Wheel Rotation Sensor Rotor Bolts [A] Front Wheel Rotation Sensor Rotor [B]

NOTE

Handle the wheel rotation sensor rotor carefully and do not apply the external force to deform it. There is a possibility that the sensor cannot read the signal correctly from the rotor.

Front Wheel Rotation Sensor Rotor Installation

- Install the front wheel rotation sensor rotor and tighten the front wheel rotation sensor rotor bolts.

Toque -Front Wheel Rotation Sensor Rotor Bolts: 4.15 N n (0.423 kgf-m, 37 in*lb)

NOTE

Handle the wheel rotation sensor rotor carefully and do not apply the external from to deform it. There is a possibility that the sensor cannot mad the signal correctly from the rotor.

Wheel Rotation Sensor Rotor Inspection

- Visually inspect the wheel rotation sensor rotor.

*If the rotor is deformed or damaged (chipped teeth [A]), replace the sensor rotor with a new one.

*If there b iron or other magnetic deposits [B], remove the deposits

Fuse Removal

Refer to the Fuse Box Fuse Removal in the Electrical System chapter.

Fuse Installation

If a fuse fails during operation, inspect the electrical system to determine the caw, and then replace it with a new fuse of proper amperage (see Fuse Installation in the Electrical System chapter).

Fuse Inspection

- Refer to the Fuse Inspection in the Electrical System chapter.

See also:

Kawasaki Z400 - Service manual > Brake Disc

Kawasaki Z400 - Service manual > Brake Disc

Brake Disc Removal Remove the wheels (see Front/Rear Wheel Removal in the Wheels/tires chapter). Remove the brake disc mounting bolts [A] and brake disc [B].

Kawasaki Z400 - Service manual > Suspension

Kawasaki Z400 - Service manual > Suspension

Exploded View

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03