Yamaha MT-03 - Service manual > Valves and valve springs

Yamaha MT-03 - Service manual > Valves and valve springs

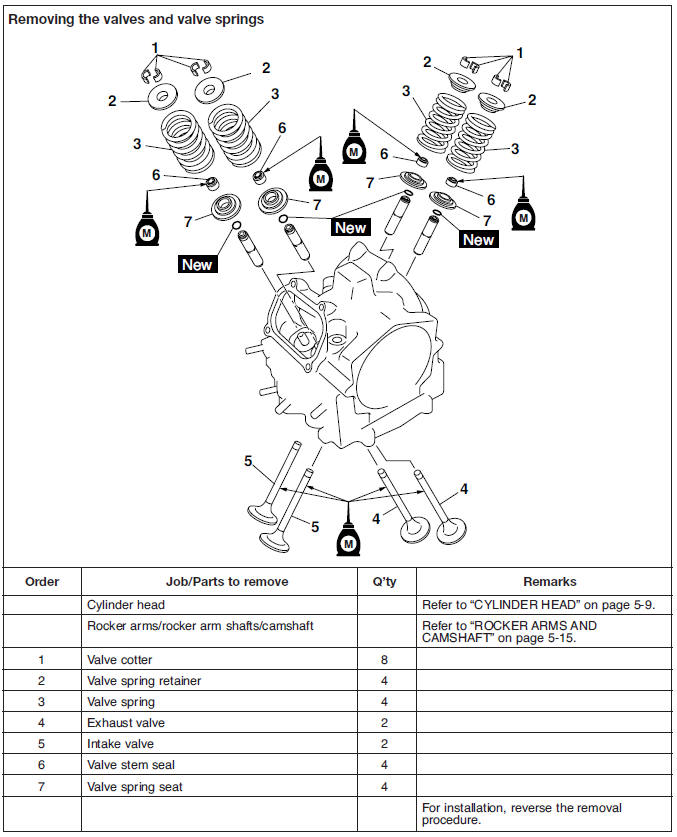

Removing the valves

The following procedure applies to all of the valves and related components.

NOTE:

Before removing the internal parts of the cylinder head (e.g., valves, valve springs, valve seats), make sure the valves properly seal.

1. Check:

- Valve sealing

Leakage at the valve seat → Check the valve face, valve seat, and valve seat width.

Refer to "CHECKING THE VALVE SEATS".

a. Pour a clean solvent "a" into the intake and exhaust ports.

b. Check that the valves properly seal.

NOTE:

There should be no leakage at the valve seat "1".

2. Remove:

- Valve cotters

NOTE:

Remove the valve cotters by compressing the valve spring with the valve spring compressor "1" and the valve spring compressor attachment "2".

Valve spring compressor

90890-04019

Valve spring compressor

90890-04019

Valve spring compressor attachment 90890-01243

3. Remove:

- Valve spring retainer "1"

- Valve spring "2"

- Valve stem seal "3"

- Valve spring seat "4"

- Valve "5"

NOTE:

Identify the position of each part very carefully so that it can be reinstalled in its original place.

Checking the valves and valve guides

The following procedure applies to all of the valves and valve guides.

1. Measure:

- Valve-stem-to-valve-guide clearance

Valve-stem-to-valve-guide clearance = Valve guide inside diameter "a" - Valve stem diameter "b"

Out of specification → Replace the valve guide.

Valve-stem-to-valve-guide

clearance

Intake

0.010-0.037 mm

(0.0004-0.0015 in)

<Limit>: 0.08 mm (0.0031 in)

Exhaust

0.025-0.052 mm

(0.0010-0.0020 in)

<Limit>: 0.10 mm (0.0039 in)

Valve-stem-to-valve-guide

clearance

Intake

0.010-0.037 mm

(0.0004-0.0015 in)

<Limit>: 0.08 mm (0.0031 in)

Exhaust

0.025-0.052 mm

(0.0010-0.0020 in)

<Limit>: 0.10 mm (0.0039 in)

2. Replace:

- Valve guide

NOTE:

To ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100 ºC (212 ºF) in an oven.

a. Remove the valve guide with the valve guide remover "1".

b. Install the new valve guide with the valve guide installer "2" and valve guide remover "1".

c. After installing the valve guide, bore the valve guide with the valve guide reamer "3" to obtain the proper valve-stem-to-valveguide clearance.

NOTE:

After replacing the valve guide, reface the valve seat.

Valve guide remover (ø6)

90890-04064

Valve guide remover (ø6)

90890-04064

Valve guide installer (ø6) 90890-04065

Valve guide reamer (ø6) 90890-04066

3. Eliminate:

- Carbon deposits (from the valve face and valve seat)

4. Check:

- Valve face.

Pitting/wear -Grind the valve face.

- Valve stem end.

Mushroom shape or diameter larger than the body of the valve stem → Replace the valve.

5. Measure:

- Valve margin thickness "a" Out of specification → Replace the valve.

Valve margin thickness

0.80-1.20 mm

(0.0315-0.0472 in)

Valve margin thickness

0.80-1.20 mm

(0.0315-0.0472 in)

6. Measure:

- Valve stem runout

Out of specification → Replace the valve.

NOTE:

- When installing a new valve, always replace the valve guide.

- If the valve is removed or replaced, always replace the valve stem seal.

Valve stem runout

0.010 mm (0.0004 in)

Valve stem runout

0.010 mm (0.0004 in)

Checking the valve seats

The following procedure applies to all of the valves and valve seats.

1. Eliminate:

- Carbon deposits (from the valve face and valve seat)

2. Check:

- Valve seat Pitting/wear → Replace the cylinder head.

3. Measure:

- Valve seat width "a" Out of specification → Replace the cylinder head.

Valve seat width

Valve seat width

Intake 1.00-1.20 mm (0.0394-0.0472 in)

Exhaust 1.00-1.20 mm (0.0394-0.0472 in)

a. Apply Mechanic's blueing dye (Dykem) onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and onto the valve seat to make a clear impression.

d. Measure the valve seat width.

NOTE:

Where the valve seat and valve face contacted one another, the blueing will have been removed.

4. Lap:

- Valve face

- Valve seat

NOTE:

After replacing the cylinder head or replacing the valve and valve guide, the valve seat and valve face should be lapped.

a. Apply a coarse lapping compound "a" to the valve face.

CAUTION:

Do not let the lapping compound enter the gap between the valve stem and the valve guide.

b. Apply molybdenum disulfide oil onto the valve stem.

c. Install the valve into the cylinder head.

d. Turn the valve until the valve face and valve seat are evenly polished, then clean off all of the lapping compound.

NOTE:

For the best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hands.

e. Apply a fine lapping compound to the valve face and repeat the steps above.

f. After every lapping procedure, be sure to clean off all of the lapping compound from the valve face and valve seat.

g. Apply Mechanic's blueing dye (Dykem) "b" onto the valve face.

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and onto the valve seat to make a clear impression.

j. Measure the valve seat width again. If the valve seat width is out of specification, reface and lap the valve seat.

Checking the valve springs

The following procedure applies to all of the valve springs.

1. Measure:

- Valve spring free length "a" Out of specification → Replace the valve spring.

Valve spring free length

Valve spring free length

Intake 40.38 mm (1.59 in) <Limit>: 38.36 mm (1.51 in)

Exhaust 40.38 mm (1.59 in) <Limit>: 38.36 mm (1.51 in)

2. Measure:

- Compressed valve spring force "a" Out of specification → Replace the valve spring.

b. Installed length

Compressed valve spring force

(installed)

171-197 N at 35.00 mm

(17.44-20.09 kg at 35.00 mm,

38.44-44.29 lb at 1.38 in)

Compressed valve spring force

(installed)

171-197 N at 35.00 mm

(17.44-20.09 kg at 35.00 mm,

38.44-44.29 lb at 1.38 in)

3. Measure:

- Valve spring tilt "a"

Out of specification → Replace the valve spring.

Spring tilt limit

2.5º/1.8 mm (2.5º/0.071 in)

Spring tilt limit

2.5º/1.8 mm (2.5º/0.071 in)

Installing the valves

The following procedure applies to all of the valves and related components.

1. Deburr:

- Valve stem end (with an oil stone)

2. Lubricate:

- Valve stem "1"

- Valve stem seal "2" (with the recommended lubricant)

Recommended lubricant

Molybdenum disulfide oil

Recommended lubricant

Molybdenum disulfide oil

3. Install:

- Valve "1"

- Valve spring seat "2"

- Valve stem seal "3"

- Valve spring "4"

- Valve spring retainer "5" (into the cylinder head)

Installing the valves

NOTE:

- Install the valve spring with the larger pitch "a" facing up.

- Install the valve spring with its painted end facing up.

b. Smaller pitch

4. Install:

- Valve cotters

NOTE:

Install the valve cotters by compressing the valve spring with the valve spring compressor "1" and the valve spring compressor attachment "2".

Valve spring compressor

98090-04019

Valve spring compressor

98090-04019

Valve spring compressor attachment 90890-01243

5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a softface hammer.

CAUTION:

Hitting the valve tip with excessive force can damage the valve.

See also:

Yamaha MT-03 - Service manual > Rocker arms and camshaft

Yamaha MT-03 - Service manual > Rocker arms and camshaft

Removing the rocker arms and camshaft 1. Loosen: Locknuts Adjusting screws

Yamaha MT-03 - Service manual > Cylinder and piston

Yamaha MT-03 - Service manual > Cylinder and piston

Removing the cylinder and piston 1. Remove: Piston pin clips "1" Piston pin "2" Piston "3"

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03