Kawasaki Z400 - Service manual > Valves

Kawasaki Z400 - Service manual > Valves

Valve Clearance Inspection

- Refer to the Valve Clearance Inspection in the Periodic Maintenance chapter.

Valve Clearance Adjustment

- Refer to the Valve Clearance Adjustment in the Periodic Maintenance chapter.

Valve Removal

- Remove: Cylinder Head (see Cylinder Head Removal) Valve Lifter and Shim

Mark and record e valve lifter and shim locations so they can be installed in their original positions.

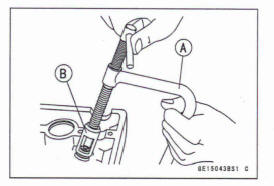

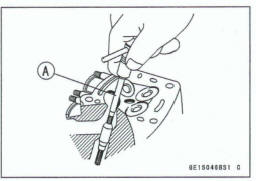

- Using the valve spring compressor assembly, remove the valve.

Special Tools -Valve Spring Compressor Assembly [A]:

57001 -241

Valve Spring Compressor Adapter,  20

[B]:

57001 -1154

20

[B]:

57001 -1154

Valve Installation

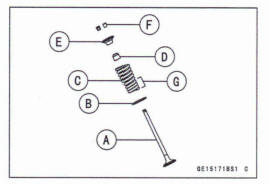

- Replace the oil seal with a new one.

- Apply engine oil to the lip of the oil seal.

- Apply a thin coat of molybdenum disulfide grease to the valve stem before valve installation.

- Install the spring so that the dosed coil end faces downwards.

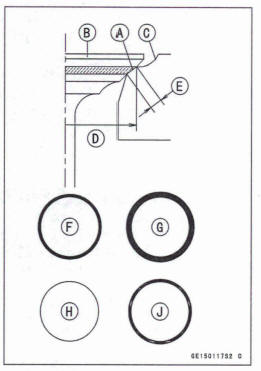

Valve Stem [A]

Spring Seat [B]

Valve Spring [C]

Oil Seal [D]

Retainer [E]

Split Keepers [F]

Closed Coil End [G]

Valve Guide Removal

- Removal: Valve (see Valve Removal) Oil seal spring Seat

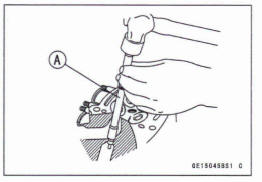

- Heat the area around the valve guide to 120 ~150ºC (248 ~ 302ºF), and hammer lightly on the valve guide arbor [A] to remove the guide from the top of the head.

Notice

Do not heat the cylinder head with a torch. This will warp the cylinder head. Soak the cylinder head in oil and heat the oil.

Special Tool - Valve Guido Arbor,

44.5: 57001 -1331

44.5: 57001 -1331

Valve Guide Installation

Apply engine oil to the valve guide outer surface before installation.

Heat the area around the valve guide hole to about 120~ 150ºC (248 ~ 302ºF).

Notice

Do not heat the cylinder head with a torch. This will warp the cylinder head. Soak the cylinder head in oil and heat the oil.

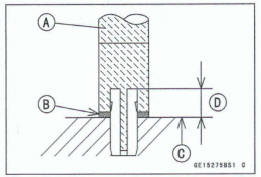

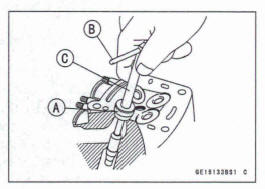

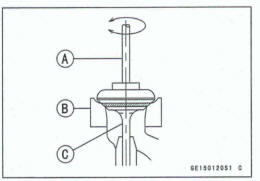

- Using the valve guide driver [A] and washer [B], press and

insert the valve guide in until the washer surface touches

the head surface [C].

15.3 - 15.5 mm (0.602 - 0.610 in.) [D]

Special Tools -Valve Guide Driver: 57001 -1 564 Washer: 57001 -1 720

- Wait until the cylinder head cools down and then ream the valve guide with the valve guide reamer [A] even if the old guide is reused.

Turn the reamer in a clockwise direction until the reamer turns freely in the guide. Never turn the reamer counterclockwise or it will be dulled.

Once the guides are reamed they must be cleaned thoroughly.

Special Tool - Valve Guide Reamer,

4.5: 57001-1333

4.5: 57001-1333

Valve-to-Guide Clearance Measurement (Wobble Method)

If a small bore gauge is not available, inspect the valve guide wear by measuring the valve to valve guide clearance with the wobble method as indicated below.

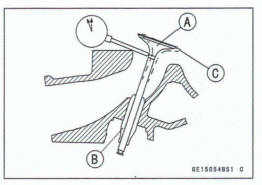

- Insert a new valve [A] into the guide [B] and set a dial gauge against the stem perpendicular to it as dose as possible to the cylinder head mating surface.

- Move the stem back and forth [C] to measure valve/valve guide clearance.

- Repeat the measurement in a direction at a right angle to the first.

*If the reading exceeds the service limit, replace the guide.

NOTE

The reading is not actual valve/valve guide clearance because the measuring point is above the guide.

Valve/valve Guide Clearance (Wobble Method) Standard:

Exhaust 0.08 - 0.16 mm (0.0031 - 0.0063 In.)

Intake 0.03 - 0.10 mm (0.0012 - 0.0038 In.)

Service Limit:

Exhaust 0.35 mm (0.014 In.)

Intake 023 mm (0.011 in.)

Valve Seat Inspection

- Remove the valve (see hive Removal).

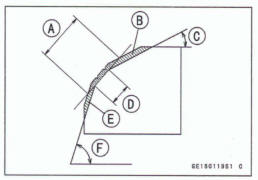

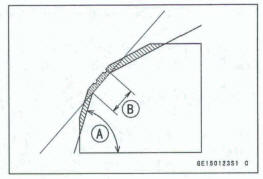

- Check the valve seating surface [A] between the valve [8] and valve seat [C].

Measure the outside diameter [D] of the seating pattern on the valve seat.

*If the outside diameter is too large or too small, repair the seat (see Valve Seat Repair).

Valve Seating Surface Outside Diameter Standard:

Exhaust 22.9 ~ 23.1 mm (OM2 ~ 0.909 In.)

Intake 26.9 ~ 27.1 mm (1.06 v 1.07 in.)

Measure the seat width [E] of the portion where there is no build-up carbon (white portion) of the valve seat with a vernier caliper.

Good [F]

*If the width is too wide [G], too narrow [H] or uneven [J], repair the seat (see Valve Seat Repair).

Valve Seating Surface Width Standard: Exhaust 0.8~ 1.2 mm (0.031~ 0.047 In.) Intake 0.5~ 1.0 mm (0.020 ~ 0.039 In.)

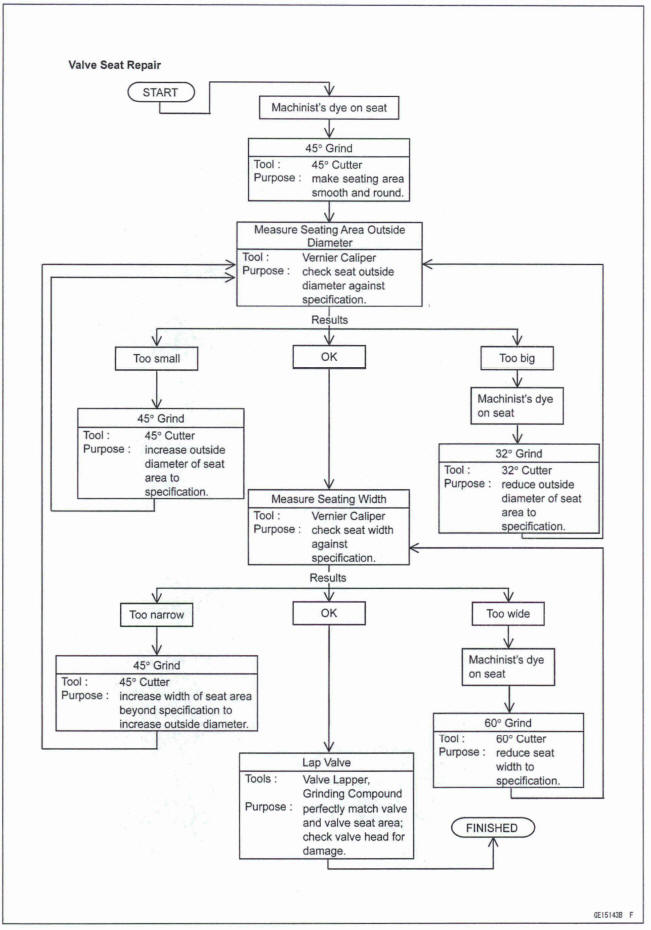

Valve Seat Repair

- Repair the valve seat with the valve seat cutters [A].

Special Tools -Valve Seat Cutter Holder Bar [B]: 5700- 1128

Valve Seat Cutter Holder,  4.5 [C]: 57001

-1 330

4.5 [C]: 57001

-1 330

Valve Seat Cutter, 45º -

27.5: 51001 1114

27.5: 51001 1114

Valve Seat Cutter, 32º -

28: 57001 -111 9

28: 57001 -111 9

Valve Seat Cutter, 60º -

30: 57001-1123

30: 57001-1123

If the manufacturer's instructions are not available, use the following procedure.

Seat Cutter Operation Care

- This valve seat cutter is developed to grind the valve for repair. Therefore the cutter must not be used for other purposes than seat repair.

- Do not drop or shock the valve seat cutter, or the diamond particles may fall off.

- Do not fail to apply engine oil to the valve seat cutter before grinding the seat surface. Also wash off ground particles sticking to the cutter with washing oil.

NOTE

Do not use a wire brush to remove the metal particles from the cutter. It will take off the diamond particles.

- Setting the valve seat cutter holder in position, operate the cutter in one hand. Do not apply too much force to the diamond portion

NOTE

Prior to grinding, apply engine oil to the cutter end during the operation, wash off any ground particles sticking to the cutter with washing oil.

- After use, wash it with washing oil and apply thin layer of engine oil before storing.

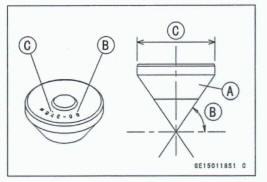

Marks Stamped on the Cutter

The marks stamped on the back of the cutter [A] represent the following.

60º........................... Cutter angle [B]

37.54  .......................

Outer diameter of cutter [C]

.......................

Outer diameter of cutter [C]

Operating Procedures

- Clean the seat area carefully.

- Coat the seat with machinist`s dye.

- Fit a 45º cutter into the holder and slide it into the valve guide.

- Press down lightly on the handle and turn it right or left.

Grind the seating surface only until it is smooth.

NOTlCE

Do not grind the seat too much. Overgrinding Will reduce valve clearance by sinking the valve into the head, If the valve, sinks too far into the head, It will be Impossible to adjust the clearance, and the cylinder head must be replaced.

- Measure the outside diameter of the seating surface with a vernier caliper.

*If the outside diameter of the seating surface is too small, repeat the 45º grind until the diameter is within the specified range.

Widened Width [A] of engagement by machining with 45º cutter Ground Volume [B] by 32º cutter 32º[C]

Correct Width [D]

Ground Volume [E] by 60º cutter 60º [F]

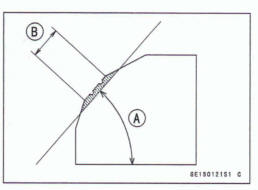

- Measure the outside diameter of the seating surface with a vernier caliper.

*If the outside diameter of the seating surface is too small, repeat the 45º grind [A] until the diameter is within the specified range.

Original Seating Surface [B]

NOTE

- Remove all pittings of flaws from 45º ground surface.

- After grinding with 45º cutter, apply thin cost of machinist's dye to mating 6urPece. This makes seating surface distinct and 32º and 60' grinding operation easier.

- When the valve guide is replaced, be sure to grind with 45º cutter for centering end good contact.

*If the outside diameter [A] of the seating surface is too large, make the 32º grind described below.

*If the outside diameter of the seating surface is within the specified range, measure the seat width as described below.

- Grind the seat at a 32º angle [B] until the seat outside diameter is within the specified range

To make the 32º grind, fit a 32º cutter into the holder, and slide it into the valve guide.

Turn the holder one turn at a time while pressing down very lightly. Check the seat after each turn.

Notice

The 32º cutter removes material very quickly. Check the seat outside diameter frequently to prevent overgrinding.

After making the 32º grind, return to the seat outside diameter measurement step above.

To measure the seat width, use a vernier caliper to measure the width of the 45º angle portion of the seat at several places around the seat.

*If the seat width is too narrow, repeat the 45º grind until the seat is slightly too wide, and then return to the seat outside diameter measurement step above.

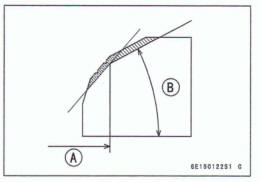

*If the seat width is too wide, make the 60º [A] grind described below.

*If the seat width is within the specified range, lap the valve to the seat as described below.

- Grind the seat at a 60º angle until the seat width is within , the specified range.

To make the 60º grind, fit 60º cutter into the holder, aid ' slide it into the valve guide.

Turn the holder, while pressing down lightly.

After making the 60º grind, return to the seat width measurement step above.

Correct Width [B]

- Lap the valve to the seat, once the seat width and outside diameter are within the ranges specified above.

- Put a little coarse grinding compound on the face of the valve in a number of places around the valve head.

- Spin the valve against the seat until the grinding compound produces a smooth, matched surface on both the seat and the valve.

- Repeat the process with a fine grinding compound.

Lapper [A] Valve Seat [B] Valve [C]

The seating area should be marked about in the middle of the valve face.

*If the seat area is not in the right place on the valve, check to be sure the valve is the correct part. If it is, it may have been refaced too much; replace it.

- Be sure to remove all grinding compound before assembly.

- When the engine is assembled, be sure to adjust the valve clearance (see Valve Clearance Inspection in the Periodic Maintenance chapter).

See also:

Kawasaki Z400 - Service manual > Cylinder Head

Kawasaki Z400 - Service manual > Cylinder Head

Cylinder Compression Measurement NOTE Use the battery which is fully charged. Warm up the engine thoroughly. Stop the engine. Remove: Air Cleaner Housing (see Air Cleaner Housing Removal in the Fuel System (DFI) chapter) Stick Coils (see Stick Coil Removal in the Electrical System chapter) Spark Plugs (see Spark Plug Replacement in the Periodic Maintenance chapter) Attach the compression gauge [A] and adapter [B] firmly into the spark plug hole. Using the starter motor, turn the mine over with the throttle fully open until the compression gauge stops rising; the compression is the highest reading obtainable.

Kawasaki Z400 - Service manual > Cylinder, Pistons

Kawasaki Z400 - Service manual > Cylinder, Pistons

Cylinder Removal Remove: Cylinder Head (see Cylinder Head Removal) Cylinder [A]

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03