Kawasaki Z400 - Service manual > Troubleshooting the DFI System

Kawasaki Z400 - Service manual > Troubleshooting the DFI System

Outline

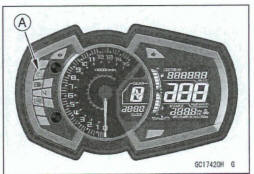

When a problem occurs with DFI system, the yellow engine warning indicator light (LED) [A] stays on after starting the engine to alert the rider.

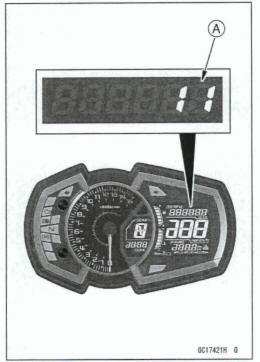

With the engine stopped and turned in the self-diagnosis mode, the service code [A] is displayed on the LCD by the number of two digits.

If the problem is with the following parts, the ECU can not recognize these problem. Therefore, the yellow engine warning indicator light (LED) does not go on, and service code is not displayed.

Fuel Pump

Fuel Pump Relay

ECU Main Relay

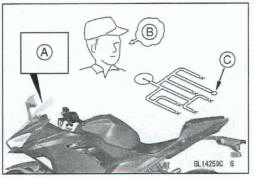

When the service code [A] is displayed, for first ask the rider about the conditions [B] of trouble, and then start to determine the cause [C] of problem.

As a pre-diagnosis inspection, check the ECU for ground and power supply, the fuel line for no fuel leaks, and for correct pressure. The pre-diagnosis items are not indicated by the yellow mine warning indicator light (LED).

Don't rely solely on the DFI self-diagnosis function, use common sense.

Even when the DFI system is operating normally, the yellow engine warning indicator light (LED) goes on may be displayed under strong electrical interference. Additional measures are not required. Turn the ignition switch off to stop the indicator light.

If the yellow engine warning indicator light (LED) of the motorcycle brought in for repair still goes on, check the service code.

When the repair has been done, the yellow engine warning indicator light (LED) goes off after the service code erasing procedure (see Service Code Erasing) is done.

When the motorcycle is down, the vehicle-down senor operates and the ECU shuts off the fuel pump relay, fuel injectors and ignition system. The ignition switch is left on.

If the starter button is pushed, the electric starter turns but the engine does not start. To start the engine again, raise the motorcycle, turn the ignition switch off, and then on.

Much of the DFI system troubleshooting work consists of confirming continuity of the wiring. The DFI parts are assembled and adjusted with precision, and it is impossible to disassemble or repair them.

When checking the DFI parts, use a digital meter which can be read two decimal place voltage or resistance.

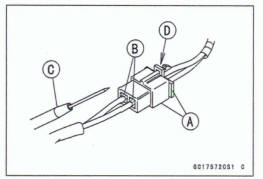

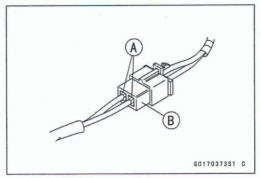

- The DFI part connectors [A] have seals [B], including the ECU. When measuring the input or output voltage with the connector joined, use the needle adapter set [C]. Insert the needle adapter inside the seal until the needle adapter reaches the terminal

Special Tool - Needle Adapter Set: 57001 -1874

Notice

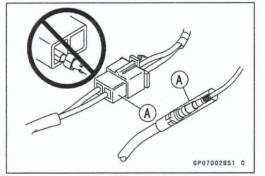

Insert the needle adapter straight along the terminal in the connector to prevent short-circuit between terminals.

- Make sure that measuring points are correct in the connector, noting the position of the lock [D] and the lead color before measurement. Do not reverse connections of a digital meter.

- Be careful not to short-circuit the leads of the DFI or electrical system parts by contact between adapters.

- Turn the ignition switch on and measure the voltage with the connector joined.

NOTICE

Incorrect, reverse connection or short circuit by needle adapters could damage the DFI or electrical system parts

After measurement, remove the needle adapters and aply silicone sealant to the seals [A] of the connector [B] for waterproofing.

Sealant - Liquid Gasket, TB1211: 56019-120

- Always check battery condition before replacing the DFI parts. A fully charged battery is a must for conducting accurate tests of the DFI system.

- Trouble may involve one, or in some cases all items.

Never replace a defective part without determining what CAUSED the problem. If the problem was caused by some other item w items, they too must be repaired or replaced, or the new replacement part will soon fail again.

- Measure the dl winding resistance when the DFI part is odd (at room temperature).

- Make sum all connectors in the circuit are dean and tight, and examine leads for signs of burning, fraying, short etc. Deteriorated Ws and bad connections can cause reappearance of problems and unstable operation of the DFI system.

If any wiring is deteriorated, replace the wiring.

- Pull each connector [A] apart and inspect it for corrosion, dirt, and damage.

If the connector Is corroded or dirty, clean it carefully. If it is damaged, replace ft. Connect the connectors securely.

- Check the wiring for continuity.

- Use the wiring diagram to find the ends of the lead which is suspected of being a problem.

- Connect a tester between the ends of the leads.

If the tester does not read about 0

, the lead is defective.

, the lead is defective.

Replace the lead or the main harness.

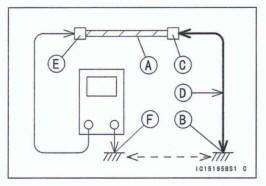

If both ends of a harness [A] are far apart, ground [B] the one end [C], using a jumper lead p] and check the continuity between the end [E] and the ground [F]. This enables to check a long harness for continuity. If the harness is open, repair or replace the harness.

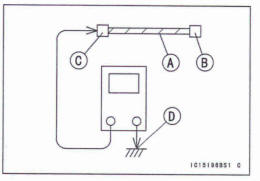

When checking a harness [A] for short circuit, open one end [B] and check the continuity between the other end [C] and ground [D]. If there is continuity, the harness has a short circuit to ground, and it must be repaired or replaced.

- Narrow dorm suspicious locations by repeating the continuity tests from the ECU connectors.

If no abnormality is found in the wiring or connectors, the DFI parts are the next likely suspects. Check the part, starting with input and output voltages. However there is no way to check the ECU itself.

If an abnormality is found, replace the affected DFI part.

If no abnormality is found On the wiring, connectors, and DFI parts, replace the ECU.

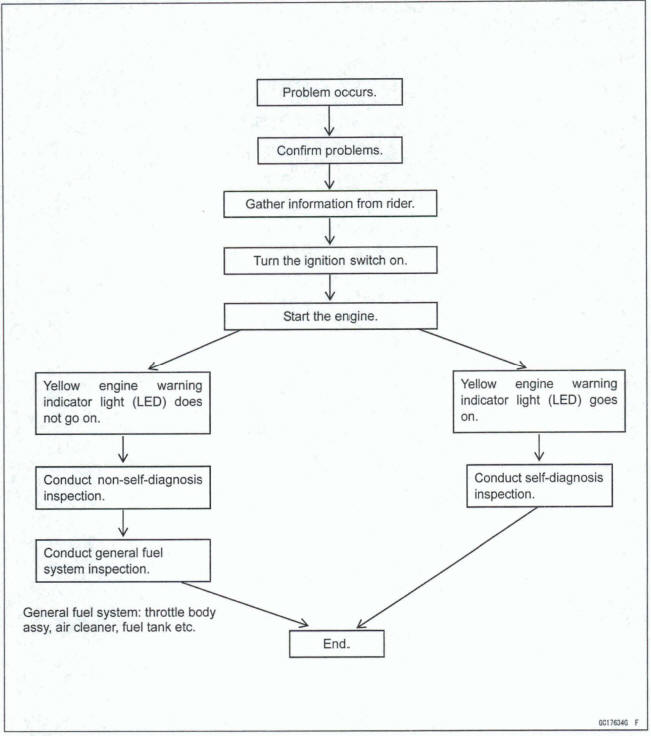

DFI Diagnosis Flow Chart

Inquiries to Rider

- Each rider reacts to problems in different ways, so it is important to confirm what kind of symptoms the rider has encountered.

- Try to find out exactly what problem occurred under exactly what conditions by asking the rider; knowing this information may help you reproduce the problem.

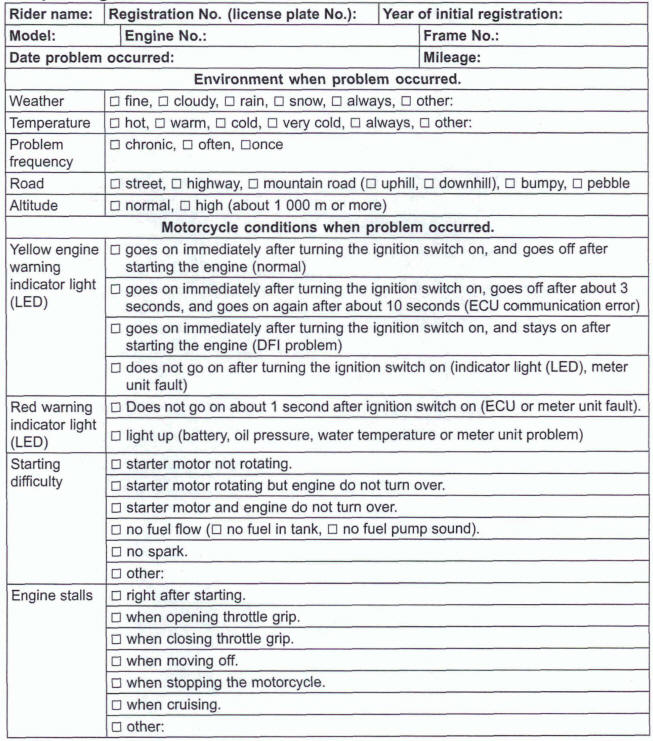

- The following sample diagnosis sheet will help prevent you from overlooking any areas, and will help you decide if it is a DFI system problem, or a general engine problem.

Sample Diagnosis Sheet

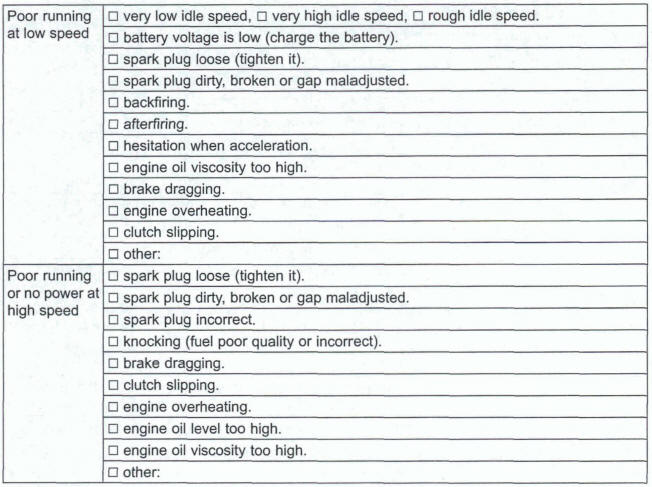

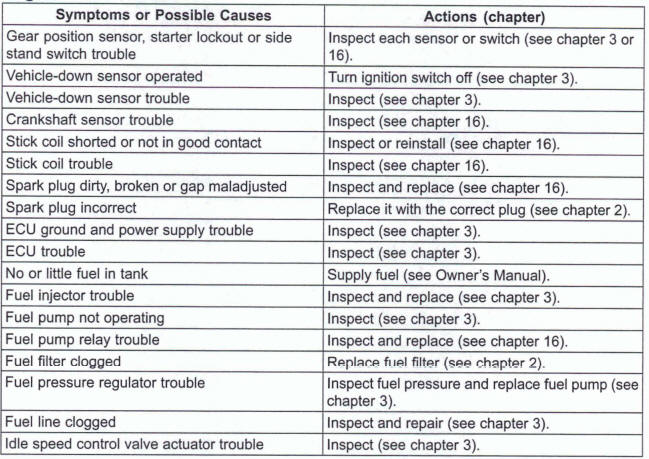

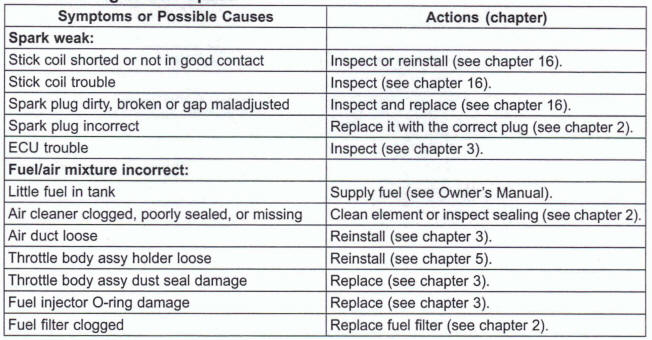

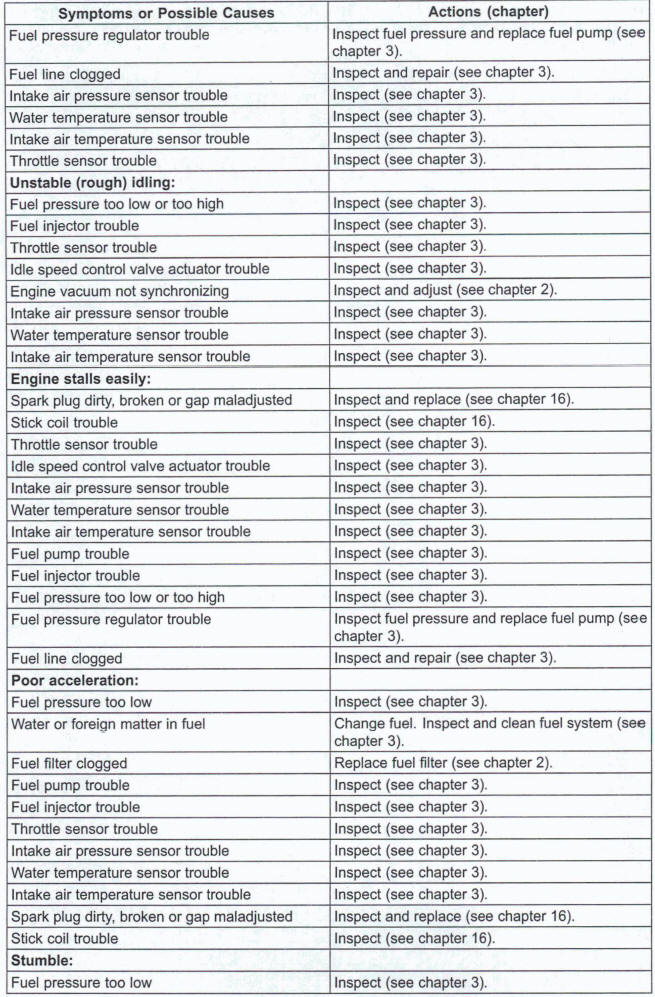

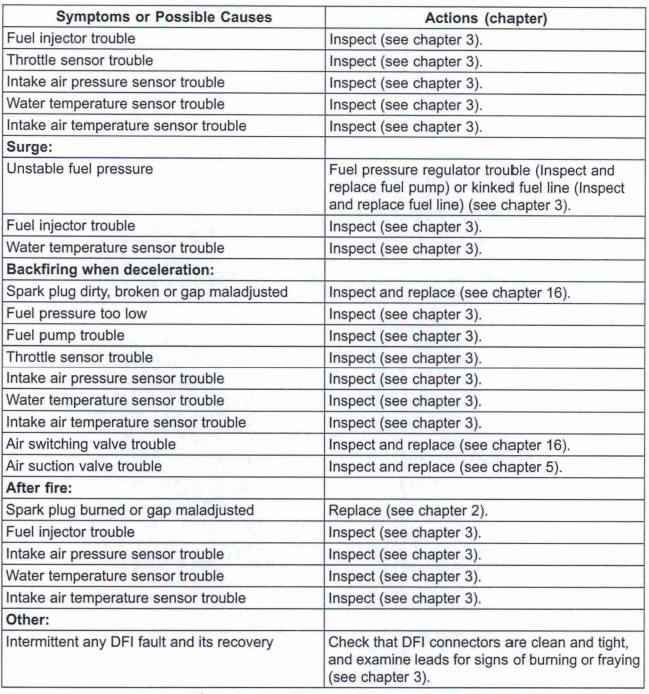

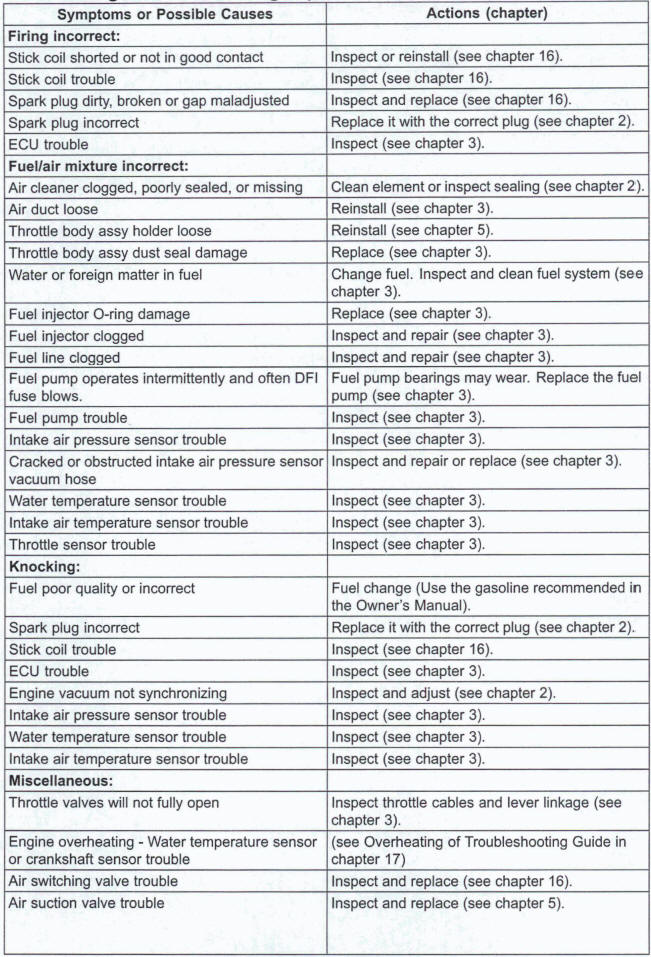

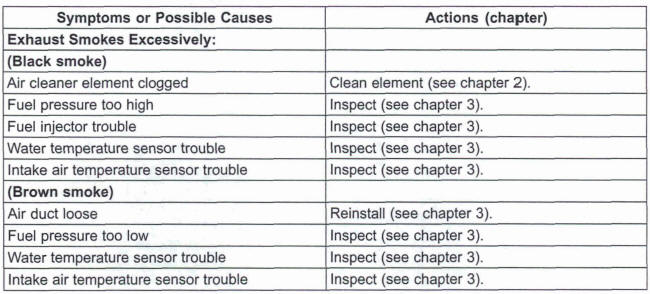

DFI System Troubleshooting Guide

NOTE

- This is not an exhaustive list, giving every possible cause for each problem listed. It is meant simply as a rough guide to assist the troubleshooting for some of the more common difficulties in DFI system.

- The ECU may be involved in the DFI electrical and ignition system troubles. If these pads and circuits are checked out good, be sure to check the ECU for ground and power supply. If the ground and power supply are checked good, replace the ECU.

Engine Won't Turn Over

Poor Running at Low Speed

Poor Running or No Power at High Speed

See also:

Kawasaki Z400 - Service manual > DFI Servicing Precautions

Kawasaki Z400 - Service manual > DFI Servicing Precautions

There are a number of important precautions that should be followed servicing the DFI system. This DFI system is designed to be used with a 12 V sealed battery as its power source. Do not use any other battery except for a 12 V sealed battery as a power source. o not reverse the battery cable connections. This will damage the ECU. To prevent damage to the DFI parts, do not disconnect the battery cables or any other electrical connections when the ignition switch is on, or while the engine Is running. Take care not to short the leads that are directly connected to the battery positive (+) terminal to the chassis ground. When charging, remove the battery from the motorcycle.

Kawasaki Z400 - Service manual > Self-Diagnosis

Kawasaki Z400 - Service manual > Self-Diagnosis

Self-Diagnosis Outline The self-diagnosis system is monitoring the following mechanisms. DFI System and Ignition System The d-diagnosis system has two modes and can be switched to another mode by operating the meter unit.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03