Triumph Street Triple S - Service manual > Secondary Air Injection

Triumph Street Triple S - Service manual > Secondary Air Injection

System Purpose and Operation

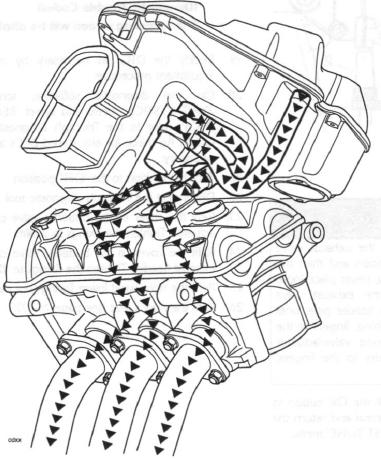

The secondary air injection system is an aid to reducing levels of pollutants in the exhaust gases. It does this by introducing a small amount of air into each exhaust port as the exhaust valve opens. The introduced air helps promote further combustion of the fuel mixture in the exhaust system after it has left the combustion chamber.

At certain specific engine speeds (determined by the factory programming of engine management system), the secondary air injection control valve is opened by the ECM and allows an air feed into the secondary air system where, each time a pair of exhaust valves open, the exhaust gases in the exhaust port create a depression which causes reed valves in the secondary air injection system to open. When open, the depression in the exhaust port draws air from the control valve, through the open reed valves, into the exhaust port. This air promotes secondary combustion of the exhaust gases in the ports and the header system.

At other engine speeds, the system is disabled by closing the control valve in the system. This allows an oxygen sensor to control air to fuel ratios. If air was fed to the exhaust system when the oxygen sensor was operational, the incoming air would cause inaccuracies in the readings sensed by the oxygen sensor (which requires access to 'raw' combustion gases) which would lead to rough running.

Secondary Air Injection Solenoid Valve

Removal

1. Remove the rider's seat.

2. Disconnect the battery, negative (black) lead first.

3. Remove the fuel tank.

4. Remove the airbox.

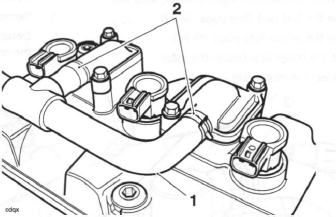

5. Release the hoses attached to the valve.

6. Disconnect the multi-plug.

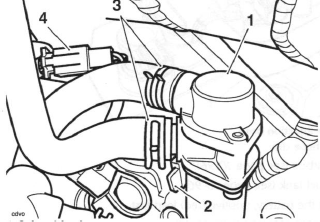

- Solenoid valve

- Retainer

- Spring hose clips

- Multiplug

7. Gently pull the valve to detach from the retainer.

Installation

1. Refit the hoses to the valve.

2. Locate the valve to the retainer.

3. Reconnect the multi-plug.

4. Refit the airbox.

5. Refit the fuel tank.

6. Reconnect the battery, positive (red) lead first.

7. Refit the rider's seat.

8. Detach the valves from the camshaft cover.

Secondary Air Injection Reed Valves

Removal

1. Remove the rider's seat.

2. Disconnect the battery, negative (black) lead first.

3. Remove the fuel tank.

4. Remove the airbox.

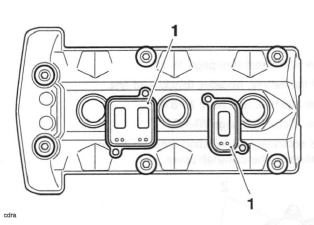

5. Detach the secondary air injection feed hoses from the reed valves on the camshaft cover.

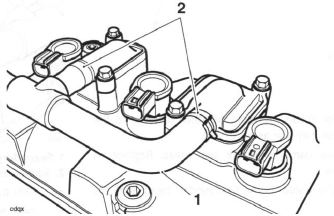

- Secondary air injection hose

- Spring-close clip

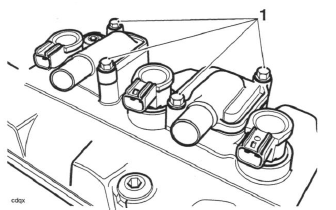

6. Release the bolts securing the valve covers to the camshaft cover.

7. Ease the valve covers from the valves.

- Valves

- Reed valves

Inspection

1. Check for cracks, bending or other damage to the valve flaps. Replace as necessary.

2. Check for damage to the seal areas. Replace as necessary.

3. Check the valve body to cylinder head seal for damage.

Installation

1. Fit the reed valves to the camshaft cover.

2. Refit the valve covers and tighten the fixings to 9 Nm.

3. Refit the secondary air injection feed hoses to the reed valves.

- Secondary air injection hose

- Spring-close hose clip

4. Refit the airbox.

5. Refit the fuel tank.

6. Reconnect the battery, positive (red) lead first.

7. Refit the rider's seat.

Evaporative Emissions Control System

California Models Only

All California models are fitted with a system to control the evaporation of fuel vapour to the atmosphere.

A carbon filled canister absorbs vapour while the engine is not running. When the engine is started, the vapour is returned to the engine and burnt.

There are two distinct phases to the system's operation, engine off and engine running. These two conditions are explained overleaf.

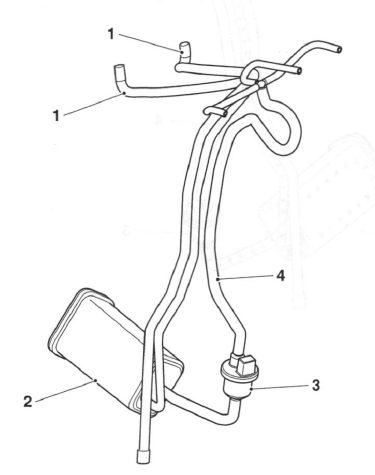

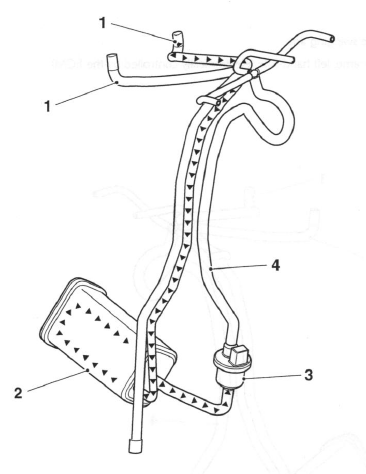

Component Locations

Carbon Filled Canister (2) - below the swinging arm.

Purge Control Valve (3)- adjacent to frame, left hand side (electronically controlled by the ECM).

- Breather hoses

- Carbon filled canister

- Purge valve

- Purge hose to throttle bodies

Evaporative Control System - Engine Off

When the engine is stationary any pressure increase in the fuel tank due to a rise in ambient temperature will cause the fuel vapour to pass down the breather hose (1) to a carbon filled canister (2) which stores the vapour.

Once in the canister, vapour cannot enter the engine because the purge valve is closed.

- Breather hoses

- Carbon filled canister

- Purge valve (closed)

- Purge hose to throttle bodies

Evaporative Control System - Engine Off

When the engine is stationary any pressure increase in the fuel tank due to a rise in ambient temperature will cause the fuel vapour to pass down the breather hose (1) to a carbon filled canister (2) which stores the vapour.

Once in the canister, vapour cannot enter the engine because the purge valve is closed.

- Breather hoses

- Carbon filled canister

- Purge valve (closed)

- Purge hose to throttle bodies

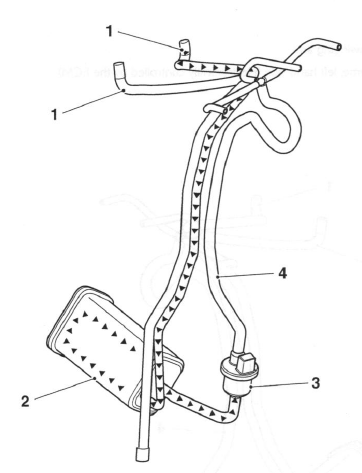

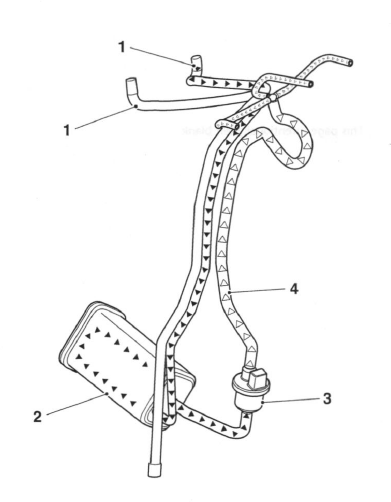

Evaporative Control System - Engine Running

When the engine is running, engine vacuum is applied to the purge hose (4) from the throttle bodies.

At certain times, the ECM opens the purge valve. The vacuum applied to the purge hose (4) now begins to draw stored vapour from the carbon filled area of the canister and returns it to the throttle bodies for burning in the engine.

In order to control the speed at which vapour is purged from the canister, the engine management system shuttles the purge control valve between open and closed positions.

- Breather hoses

- Carbon filled canister

- Purge valve (open under ECM control)

- Purge hose to throttle bodies

See also:

Triumph Street Triple S - Service manual > Exhaust System - Daytona 675

Triumph Street Triple S - Service manual > Exhaust System - Daytona 675

Removal Warning: If the engine has recently been running, the exhaust system will be hot. Before working on or near the exhaust system, allow sufficient time for the exhaust system to cool as touching any part of a hot exhaust system could cause burn injuries.

Triumph Street Triple S - Service manual > Cooling

Triumph Street Triple S - Service manual > Cooling

Exploded View - Cooling System - Daytona 675

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03