Honda CB500X - Owner's Manual > Tire Puncture

Honda CB500X - Owner's Manual > Tire Puncture

Repairing a puncture or removing a wheel requires special tools and technical expertise.

We recommend you have this type of service performed by your dealer.

After an emergency repair, always have the tire inspected/replaced by your dealer.

Emergency Repair Using a Tire Repair Kit

If your tire has a minor puncture, you can make an emergency repair using a tubeless tire repair kit.

Follow the instructions provided with the emergency tire repair kit.

Riding your motorcycle with a temporary tire repair is very risky. Do not exceed 30 mph (50 km/h). Have the tire replaced by your dealer as soon as possible.

WARNING Riding your motorcycle with a temporary tire repair can be risky. If the temporary repair fails, you can crash and be seriously injured or killed.

If you must ride with a temporary tire repair, ride slowly and carefully and do not exceed 30 mph (50 km/h) until the tire is replaced.

Removing Wheels

Follow these procedures if you need to remove a wheel in order to repair a puncture.

CB500XA only

When removing and installing the wheel, be careful not to damage the wheel speed sensor and pulser ring.

Front Wheel

Removal

1. Place your motorcycle on a firm, level surface.

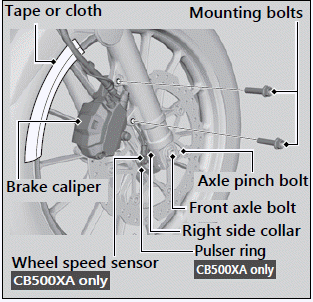

2. Cover the right side of the front wheel and brake caliper with protective tape or cloth.

3. On the right side, remove the mounting bolts and brake caliper.

- Support the brake caliper assembly so that it doesn't hang from the brake hose. Do not twist the brake hose.

- Avoid getting grease, oil, or dirt on the disc or pad surfaces.

- Do not pull the front brake lever while the brake caliper is removed.

- Take care to prevent the brake caliper from scratching the wheel during removal.

4. Remove the front axle bolt.

5. Loosen the right axle pinch bolt.

6. Support your motorcycle securely and raise the front wheel off the ground using a maintenance stand or a hoist.

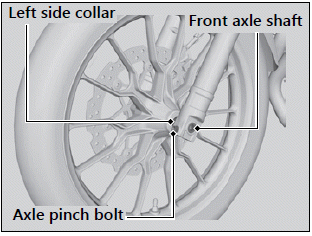

7. Loosen the left axle pinch bolt.

8. On the left side, withdraw the front axle shaft, and remove the side collars and wheel.

Installation

1. Attach the right and left side collars in their original location on the wheel.

2. On the left side, place the wheel between the fork legs and insert the front axle shaft to the end, through the left fork leg and wheel hub.

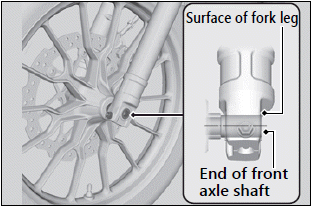

3. Align the end of the front axle shaft with the surface of the fork leg.

4. Tighten the left axle pinch bolts to hold the axle shaft.

5. Install and tighten the axle bolt.

Torque: 38 lbf-ft (51 N-m, 5.2 kgf-m)

6. Loosen the left axle pinch bolt.

7. Tighten the right axle pinch bolt.

Torque: 16 lbf-ft (22 N-m, 2.2 kgf-m)

8. Install the brake caliper and tighten the mounting bolts.

Torque: 22 lbf-ft (30 N-m, 3.1 kgf-m)

- Take care to prevent the brake caliper from scratching the wheel during installation.

- Use new mounting bolts when installing the brake caliper.

NOTICE When installing a wheel or caliper into original position, carefully fit the brake disc between the pads to avoid scratching them.

9. Lower the front wheel on the ground.

10.Apply the brake lever several times. Then, pump the fork several times.

11.Retighten the left axle pinch bolt.

Torque: 16 lbf-ft (22 N-m, 2.2 kgf-m)

12.Raise the front wheel off the ground again, and check that the wheel rotates freely after you release the brake.

13.Uncover the protective tape or cloth.

If a torque wrench was not used for installation, see your dealer as soon as possible to verify proper assembly.

Improper assembly may lead to loss of braking capacity.

Rear Wheel

Removal

1. Place your motorcycle on a firm, level surface.

2. Support your motorcycle securely and raise the rear wheel off the ground using a maintenance stand or a hoist.

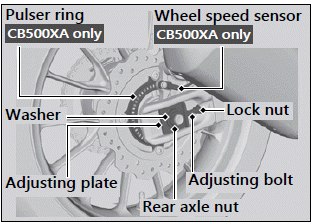

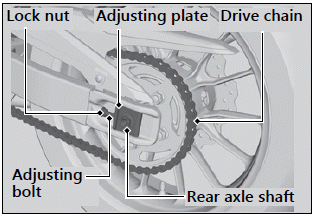

3. Loosen the rear axle nut, lock nuts and turn the adjusting bolts so the rear wheel can be moved all the way forward for maximum drive chain slack.

4. Remove the drive chain from the driven sprocket by pushing the rear wheel forward.

5. Remove the rear axle nut and washer.

6. Remove the rear axle shaft and adjusting plates.

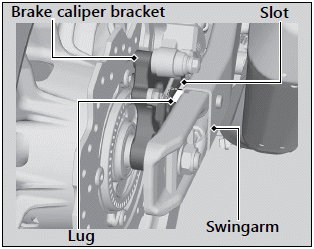

7. Remove the brake caliper bracket, rear wheel and side collars.

- Support the brake caliper assembly so that it doesn't hang from the brake hose. Do not twist the brake hose.

- Avoid getting grease, oil, or dirt on the disc or pad surfaces.

- Do not push the brake pedal while the wheel is removed.

Installation

1. To install the rear wheel, reverse the removal procedure.

- Take care to prevent the brake caliper from scratching the wheel during installation.

NOTICE When installing a wheel or caliper into original position, carefully fit the brake disc between the pads to avoid scratching them.

2. Make sure that the slot on the brake caliper bracket is positioned in the lug on the swingarm.

3. Adjust the drive chain slack.

4. Install and tighten the rear axle nut.

Torque: 65 lbf-ft (88 N-m, 9.0 kgf-m)

5. Hold the adjusting bolts and tighten the lock nuts.

Torque: 20 lbf-ft (27 N-m, 2.8 kgf-m)

6. After installing the wheel, apply the brake pedal several times, then check if the wheel rotates freely. Recheck the wheel if the brake drags or if the wheel does not rotate freely.

If a torque wrench was not used for installation, see your dealer as soon as possible to verify proper assembly.

Improper assembly may lead to loss of braking capacity.

See also:

Honda CB500X - Owner's Manual > Engine Will Not Start

Honda CB500X - Owner's Manual > Engine Will Not Start

Starter Motor Operates But Engine Does Not Start Check the following items: Check the correct engine starting sequence. Check that there is gasoline in the fuel tank. Check if the PGM-FI malfunction indicator lamp (MIL) is on. If the indicator lamp is on, contact your dealer as soon as possible.

Honda CB500X - Owner's Manual > Electrical Trouble

Honda CB500X - Owner's Manual > Electrical Trouble

Battery Goes Dead Charge the battery using a motorcycle battery charger. Remove the battery from the motorcycle before charging. Do not use an automobile-type battery charger, as these can overheat a motorcycle battery and cause permanent damage. If the battery does not recover after recharging, contact your dealer.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03