Kawasaki Z400 - Service manual > Front Fork

Kawasaki Z400 - Service manual > Front Fork

Front Fork Removal (Each Fork Leg)

- Remove: Middle Fairings (see Middle Fairing Removal in the Frame chapter) Front Wheel (see Front Wheel Removal in the Wheels/Tires chapter) Front Fender (see Front Fender Removal in the Frame chapter)

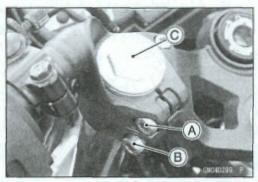

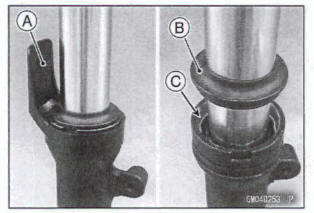

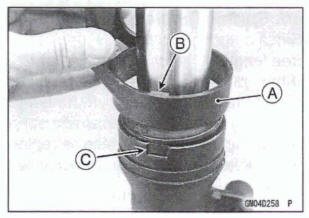

*If fork leg is to be disassembled, loosen the handlebar damp bolt [A] and upper front fork damp bolt [B], front fork top plug [C] beforehand.

- Loosen: Handlebar Clamp Bolt Upper Front Fork Clamp Bolt Lower Front Fork Clamp Bolts [D]

- With a twisting motion, remove the fork leg down and out.

Front Fork Installation (Each Fork Leg)

- Install the fork leg.

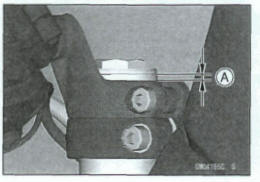

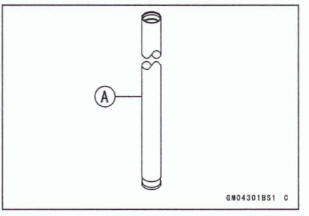

- Position the fork leg so that top end of the inner tube as

shown.

About 3 mm (0.1 in.) [A]

- Tighten:

Torque - Lower Front Fork Clamp Bob: 23 N-m (2.3 kgf-m, 17 R-lb)

NOTE

Tighten the two lower front fork clamp bolts alternately two times to ensure even Tightening toque

*Tighten the front fork top plug to the specified torque if the front fork top plug is removed

Torque - Front Fork Top Plugs: 30 N*m (3.1 kgf-m, 22 ft*lb)

NOTE

Tighten the top plug before tightening the handlebar clamp bolt and upper front fork clamp bolt.

- Tighten

Toque - Upper Front Fork Clamp Bolt: 20 N-m (2.0 kgf*m, 1 5 ft*lb) Handlebar Clamp Bolt 25 N-m (2.5 kgf*m, 18 ft*lb)

- Install the removed parts (see appropriate chapters).

Front Fork Oil Change

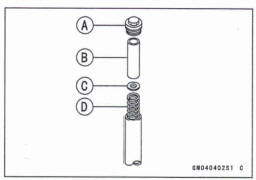

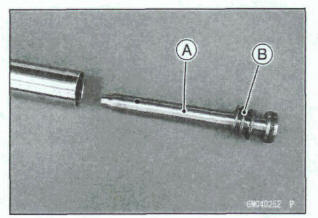

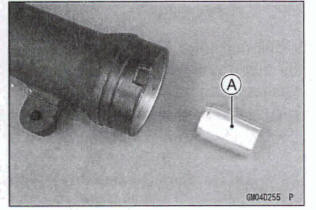

- Remove: Front Fork (see Front Fork Removal) Front Fork Top Plug [A] with O-ring Spacer [B] Fork Spring Seat [C] Fork Spring [D]

- Drain the fork oil into a suitable container [A].

- Pump the inner tube up and down at least 10 times to expel the oil from the fork.

- Hold the fork tube upright, pour in the type and amount of fork oil specified.

Suspension Oil- SS-8 (1 L): 44091-0007

Amount (Per Side):

When changing oil: Approx. 450 mL (15.2 US oz.)

After disassembly and completely dry: 526+- 2.5 mL (17.8 +- 0.085 US oz.)

NOTE

Move the outer tube up and down a few times to remove the air that is trapped in the fork oil in order to stabilize the oil level.

- Hdd the outer tube vertically in a vise and compress the fork completely.

- Wait until the dl level stabilize.

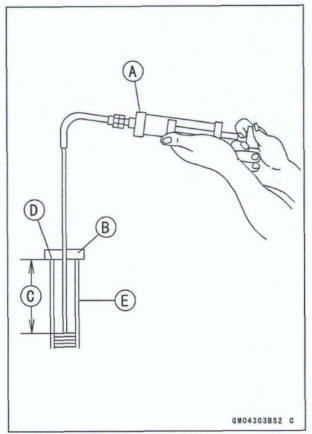

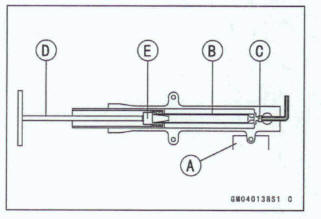

- Use the fork oil level gauge [A] to measure the distance between the top of the inner tube to the oil leveG

Special Tool - Fork Oil Level Gauge: 57001-12901

- Set the oil level gauge stopper [B] so that the distance [C] from the bottom of the stopper to the lower end of the pipe is the standard oil level distance.

- A correct measurement can not be obtained unless the level gauge pipe is placed in the center of the inner tube.

Fork Oil Level (fully compressed, without fork spring)

Standard: 88 +-2 mm (3.5 M.08 In.)

- Place the stopper of the level gauge at the top [D] of the inner tube [E] and pull the handle slowly to draw out the excess oil from fork into the gauge, thus attaining the standard level

If not oil is drawn out, there is not enough oil in the fork.

Pour in some more oil and measure again

- Repeat the same procedure for adjusting the other fork.

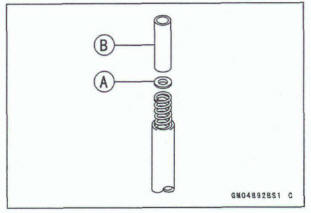

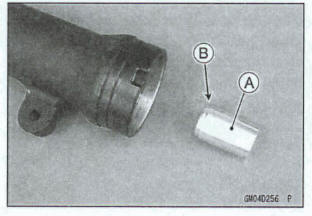

- Install: Fork Spring Fork Spring Seat [A] spacer [B]

- Replace the top plug O-ring with a new one.

- Apply grease to the top plug O-ring.

- Install: Front Fork Top Plug Front Fork (see Front Fork Installation)

Front Fork Disassembly

- Drain the fork oil (see Front Fork Oil Change).

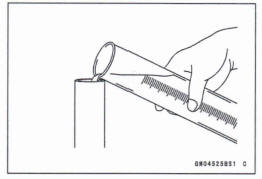

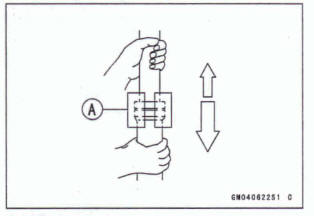

- Hold the fork leg horizontally in a vise [A].

- Hold the cylinder unit [B] by using the special tools.

Special Tools - Fork Cylinder Holder Handle [C]: 57001 -1 83 Fork Cylinder Holder Adapter (Dl: 57001 1057

- Remove the Allen bolt [E] and gasket from the bottom of the outer tube.

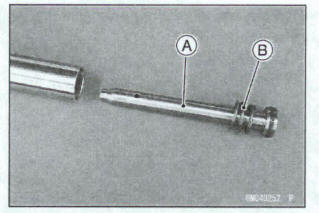

- Remove the cylinder unit [A] and spring [B] from the inner tube

- Remove the following parts from the top of the outer tube.

Fork Guard [A] Dust Seal [B] Retaining Ring [C]

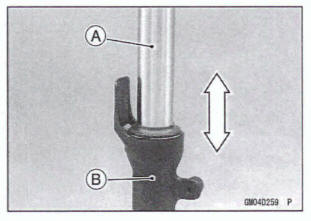

Use the fork outer tube weight [A] to separate the inner tube from the outer tube. Holding the inner tube by hand in a vertical position, pull down the outer tube several times to pull out the inner tube.

Special Tool - Fork Outer Tube Weight: 57001-1218

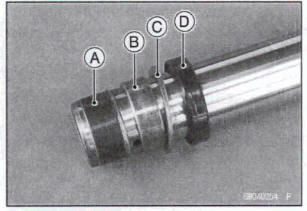

- Remove: Inner Guide Bushing [A] Outer Guide Bushing [B] Washer [C] Oil Seal [D]

Remove the cylinder base [A] from the bottom of the outer tube.

Front Fork Assembly

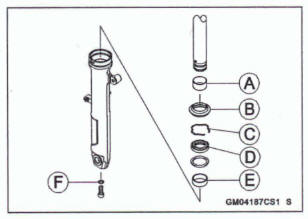

Replace the following parts with new ones.

Inner Guide Bushing [A] Dust Seal [B] Retaining Ring [C] Oil Seal [D] Outer Guide Bushing [E] Front Fork Bottom Allen Bolt Gasket [F]

- Install the new inner guide bushing to the groove on the inner tube.

- Insert the cylinder unit [A] and the spring [B] into the inner tube.

- Install the cylinder base [A] so that stepped side [B] aces downward into the bottom groove of the outer tube.

- Install the inner tube and cylinder unit as a set into the outer tube.

- Install a new bottom Allen bolt gasket.

- Apply a non-permanent locking agent to the threads of the bottom Allen bolt.

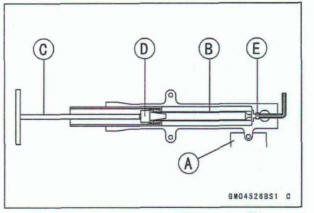

- Hold the outer tube horizontally in a vise [A], stop the cylinder unit [B] with the special tools, then tighten the Allen bolt [C].

Special Tools - Fork Cylinder Holder Handle [D]: 57001-183 Fork Cylinder Holder Adapter [E]: 57001 -1 057

Torque - Front Fork Bottom Allen Bolts: 20 N-m (2.0 kgf*m, 15 ft-lb)

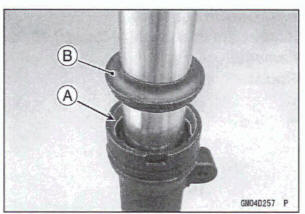

- In stall the outer guide bushing [A] and washer [B] into the outer tube using the fork oil seal driver [C], until the washer is bottomed.

Special Tools - Fork Oil Seal Driver,

41 : 57001 -1288 or

Fork Oil Seal Driver Weight,

41 : 57001 -1288 or

Fork Oil Seal Driver Weight,  26

~

26

~ 46:

57001 -1 795

Fork Oil Seal Driver Attachment,

46:

57001 -1 795

Fork Oil Seal Driver Attachment,  36

~

36

~ 46:

57001 -1 798

46:

57001 -1 798

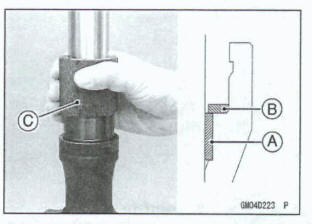

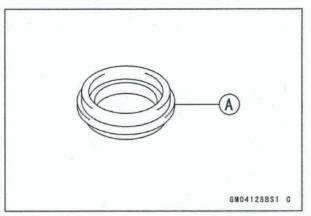

- Apply grease to the oil seal lips, and install the oil seal [A] to the outer tube from the top.

- Install the oil seal with its lip side [B] facing up.

- In stall the oil seal into the outer tube using the fork oil seal driver [C] until the oil seal is bottomed

Special Tools - Fork Oil Seal Driver,

41 : 57001 -1288 or

Fork Oil Seal Driver Weight,

41 : 57001 -1288 or

Fork Oil Seal Driver Weight,  26 -

26 - 46:

57001 -1 795

Fork Oil Seal Driver Attachment,

46:

57001 -1 795

Fork Oil Seal Driver Attachment,  36

-

36

- 46:

57001 -1 798

46:

57001 -1 798

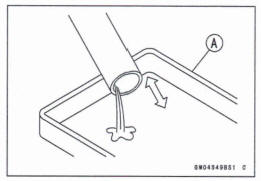

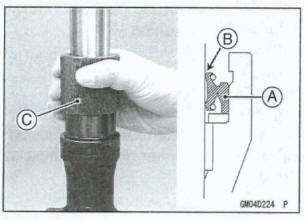

- Install the retaining ring [A] to the groove in the outer tube.

- Install the dust seal [B]

Inner Tube, Outer Tube Inspection

- Visually inspect the inner tube [A].

*If there is any damage, replace the inner tube. Since damage to the inner tube damages the oil seal and dust seal, replace the oil seal and dust seal whenever the inner tube is replaced

NOTICE

If the inner tube is badly bent or creased, replace it. Excessive bending, followed by subsequent straightening, can weaken the inner tube.

- Temporarily assemble the inner [A] and outer [B] tubes, and pump them back and forth manually to check for smooth operation

*If you fee1 binding or catching, the inner and outer tubes must be replaced.

Warning

A straightened inner or outer fork tube may fall in use, possibly causing an accident resulting in serious injury or death. Replace a badly bent or damaged inner or outer tub and inspect the other tube carefully before musing it.

Dust Seal Inspection

- Inspect the dust seal [A] for any signs of deterioration or damage.

*Replace it if necessary.

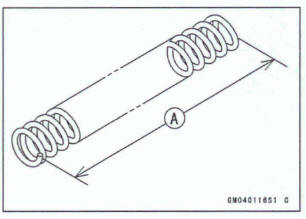

Fork Spring Tension Inspection

- Since a spring becomes shorter as ii weakens, check its free length [A] to determine its condition.

*If the spring of either fork leg is shorter than the service limit, it must be replaced. If the length of s replacement spring and that of the remaining spring vary greatly, the remaining spring should also be replaced in order to keep the fork legs balanced for motorcycle stability.

Fork Spring Free Length Standard: 297.5 mm (11.71 in.) Service Limit: 293 mm (11.5 In.)

See also:

Kawasaki Z400 - Service manual > Suspension

Kawasaki Z400 - Service manual > Suspension

Exploded View

Kawasaki Z400 - Service manual > Rear Shock Absorber

Kawasaki Z400 - Service manual > Rear Shock Absorber

Spring Preload Adjustment Using the wrench [A] from the tool kit, turn the adjusting nut to adjust the spring preload. The standard adjuster setting is 2nd position.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03